Leave Your Message

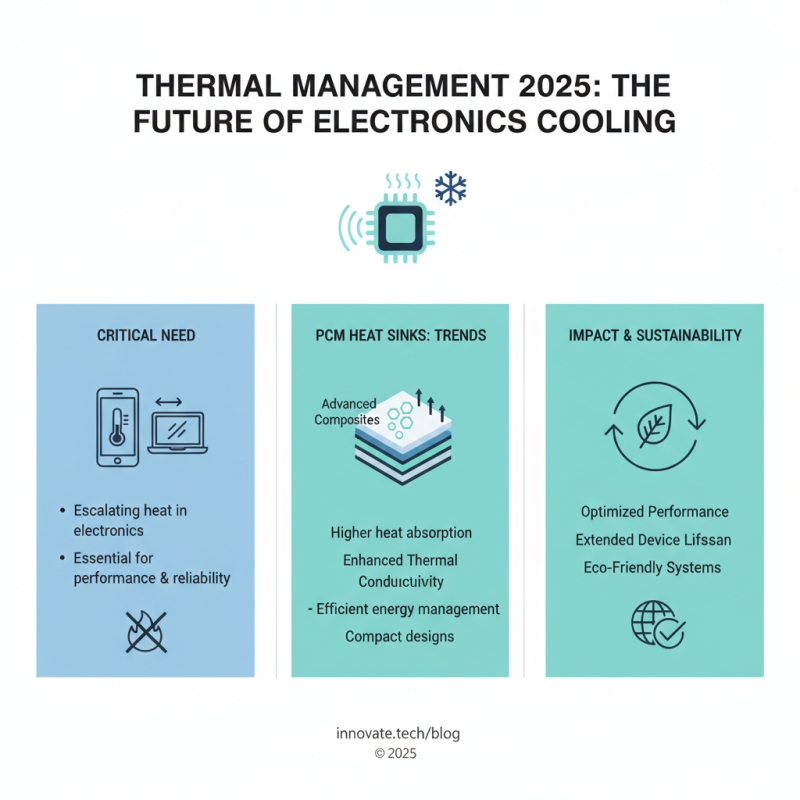

In the ever-evolving landscape of thermal management solutions, the demand for innovative designs of PCM heat sinks is at an all-time high. As technology continues to push boundaries, engineers and designers are challenged to develop systems that not only improve efficiency but also enhance cooling capabilities. According to Dr. Emily Foster, a leading expert in thermal management, "The future of electronics hinges on our ability to effectively manage heat, and PCM heat sinks are at the forefront of this revolution."

As we look towards 2025, the advancements in PCM heat sink design promise to redefine industry standards. By optimizing phase change materials, manufacturers can create heat sinks that respond dynamically to varying thermal loads, providing superior heat dissipation while minimizing space requirements. This forecast highlights the importance of incorporating state-of-the-art materials and engineering techniques, allowing for customizable solutions that cater to specific application needs.

The focus on innovative PCM heat sink designs not only enhances performance but also paves the way for sustainable practices in the industry. By embracing these new technologies, engineers can contribute to more reliable and energy-efficient systems—ultimately paving the way for a cooler, more efficient future in thermal management solutions.

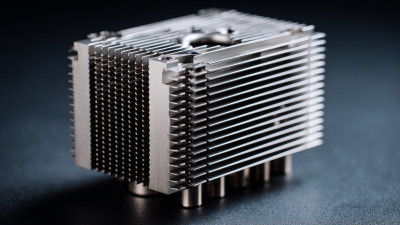

As we move into 2025, the importance of effective thermal management continues to escalate, particularly in electronic applications where heat dissipation is critical. One of the notable trends in phase change material (PCM) heat sink designs is the integration of advanced materials that enhance thermal conductivity while minimizing weight. Engineers are increasingly opting for composites that offer a higher heat absorption capacity, allowing for more efficient energy management in compact designs. This progression not only optimizes performance but also contributes to the overall sustainability of electronic systems.

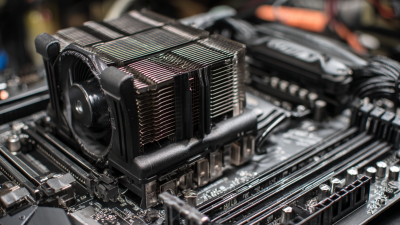

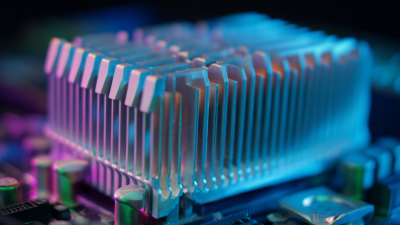

Another emerging trend is the incorporation of innovative geometries in heat sink designs, which allows for improved airflow and heat distribution. Designs that leverage optimized fin structures and surface enhancements are becoming more prevalent, enabling greater heat transfer efficiency. Additionally, adaptive features, such as variable geometry that responds to changing thermal loads, are gaining traction. This adaptability ensures that devices remain cool under varying operational conditions, ultimately prolonging their lifespan and reliability. Together, these advancements are paving the way for next-generation PCM heat sinks designed to meet the demands of modern technology in 2025 and beyond.

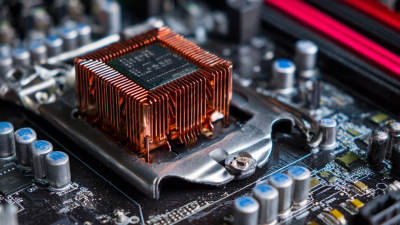

The efficiency of Phase Change Material (PCM) heat sinks is heavily influenced by the selection of materials used in their construction. One of the primary factors in enhancing thermal management solutions is thermal conductivity. Metals like aluminum and copper are often chosen for their superior heat conduction properties, allowing for rapid heat dissipation. In addition, incorporating materials such as graphite and ceramic composites can further improve performance by providing additional avenues for heat transfer and increasing the overall thermal mass.

Another essential material consideration is the PCM itself, which facilitates thermal energy storage and release. Innovative formulations of PCMs, designed to undergo phase changes at specific temperatures, can greatly enhance a heat sink's ability to regulate temperature. Recent advancements in bio-based or organic materials offer eco-friendly options that still maintain excellent thermal properties. These materials not only improve the efficiency of heat sinks but also cater to the growing demand for sustainable solutions in thermal management applications. The interplay of these advanced materials is critical in developing the top PCM heat sink designs of 2025, positioning them as vital components in modern thermal management systems.

| Design Name | Material Used | Thermal Conductivity (W/mK) | Weight (g) | Applications |

|---|---|---|---|---|

| Ultra-Thin Active Heat Sink | Copper-Aluminum Composite | 350 | 50 | Consumer Electronics |

| High Performance Cooling Plate | Graphene Matrix | 1200 | 80 | Data Centers |

| Compact Fin Design | Aluminum Alloy | 200 | 45 | LED Lighting |

| Optimized Heat Pipe Array | Copper Heat Pipes with Aluminium Fins | 250 | 90 | Industrial Equipment |

| Advanced Sintered Heat Sink | Sintered Metal Matrix | 350 | 70 | High-Performance Computing |

The advancements in heat sink technology in 2025 are pivotal for improving thermal management solutions across various applications. A recent report indicates that the thermal resistance of leading heat sink designs has dropped by approximately 25% compared to previous years, thanks to enhanced materials and innovative geometric configurations. Notably, the integration of advanced fin structures and the use of lightweight metals enable these heat sinks to dissipate heat more efficiently, crucial for high-performance computing systems and electronics that demand optimal thermal management.

In analyzing the performance metrics of the latest heat sink options, thermal conductivity emerges as a significant indicator. Current models exhibit an average thermal conductivity improvement of 15% over previous generations, largely attributed to novel aluminum alloys and copper composites. Additionally, computational simulations are increasingly being utilized to predict heat dissipation efficiency, translating theoretical performance into practical scenarios. The emphasis on performance metrics, such as effective surface area and airflow optimization, further solidifies the role of heat sinks as essential components in enhancing overall system reliability and longevity.

The comparative cost analysis of Phase Change Material (PCM) heat sinks reveals significant insights into the effectiveness of thermal management solutions across various industries. According to a recent report by Global Market Insights, the PCM heat sink market is projected to grow at a CAGR of 12.3% from 2023 to 2030, driven by increasing demand for efficient thermal management systems in sectors such as electronics, automotive, and renewable energy.

When analyzing costs, PCM heat sinks, while initially expensive, can yield substantial long-term savings by reducing energy consumption and extending the lifecycle of electronic components.

In terms of cost per kilowatt-hour, recent studies indicate that PCM heat sinks can be up to 30% more efficient than traditional metal heat sinks. This efficiency translates to lower operational costs and improved performance in high-temperature environments. For instance, an analysis presented by TechSci Research highlights that industries adopting PCM solutions have reported a 15-20% reduction in cooling costs, allowing better allocation of financial resources toward other operational needs. As businesses increasingly prioritize sustainability and efficiency, the upfront investment in PCM heat sinks is gradually being justified by their enhanced performance and overall cost-effectiveness in thermal management.

As we look towards 2025, the evolution of phase change material (PCM) heat sinks is set to transform thermal management strategies across various industries. PCM technology leverages materials that absorb and release thermal energy during phase transitions, significantly enhancing efficiency in thermal regulation. According to a recent report by the International Journal of Thermal Sciences, PCM-enabled heat sinks can achieve up to a 30% improvement in thermal performance compared to traditional designs. This advancement not only aids in maintaining optimal operating temperatures in electronic devices but also prolongs their lifespan, making them increasingly vital in sectors like aerospace, automotive, and data centers.

Future innovations in PCM heat sink technology are likely to incorporate advanced composites and nanomaterials that further increase heat absorption capabilities. Researchers are exploring the use of hybrid PCMs that combine multiple materials to optimize performance across a wider temperature range. Additionally, smart PCM systems integrated with IoT capabilities could enable real-time monitoring and adjustments, enhancing energy efficiency by adapting to fluctuating thermal loads. This adaptability could result in energy savings of up to 20%, as noted in recent findings from the Thermal Management Society.

Tips: When considering PCM heat sink options, look for designs that offer customizable thermal profiles to meet specific application needs. Additionally, the integration of simulation tools can provide insights into the thermal performance before deployment, ensuring your thermal management solution is tailored for optimal effectiveness. Always prioritize solutions that consider long-term sustainability and material efficiency for enhanced operational performance.