Leave Your Message

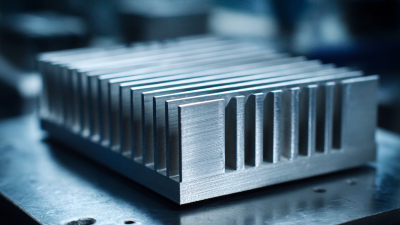

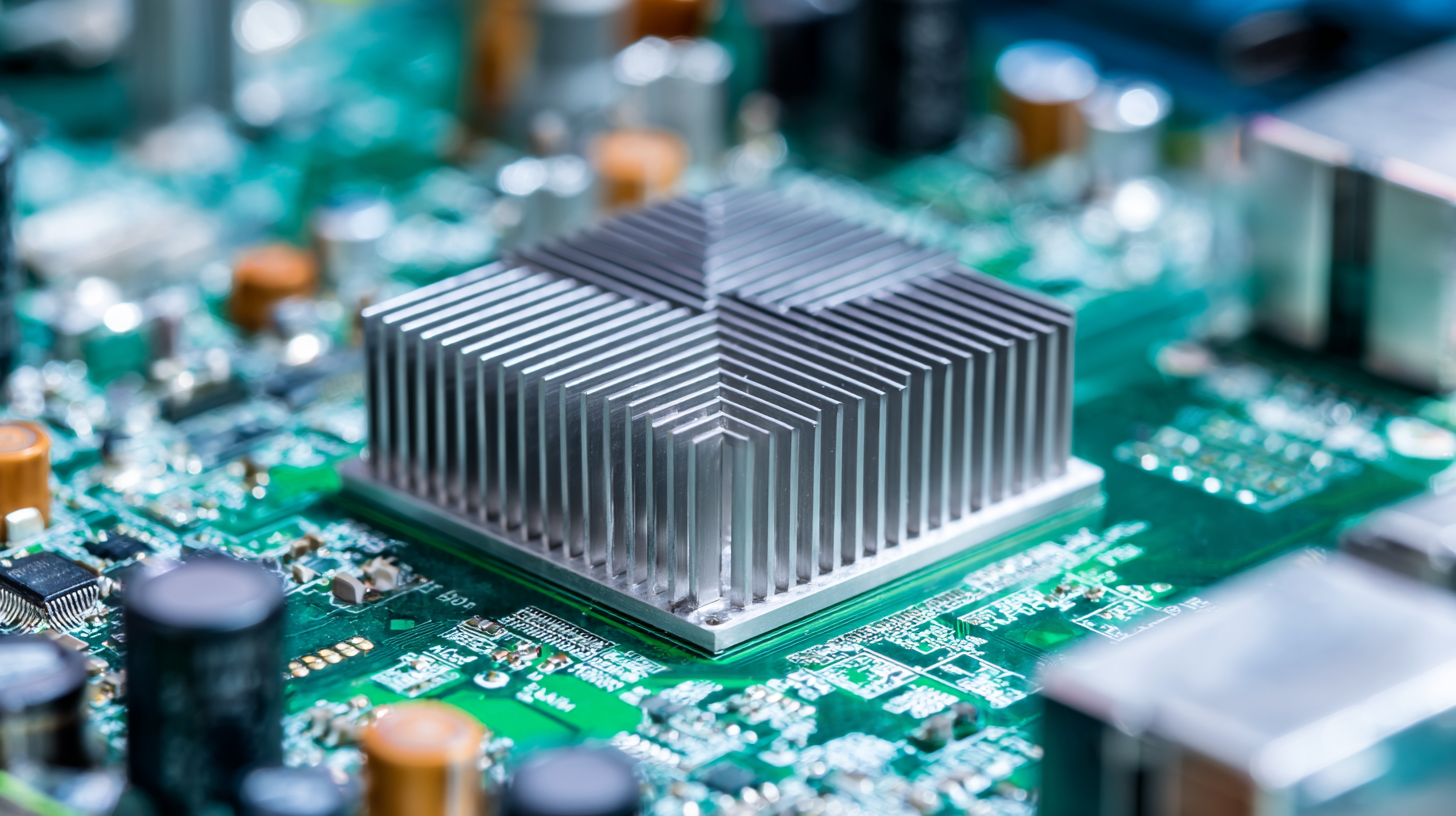

In the realm of thermal management, the aluminum heat sink stands out as a critical component for enhancing the efficiency of electronic devices. As technology evolves, the need for effective thermal management solutions becomes increasingly paramount, particularly in high-performance applications. Dr. Samuel Thompson, a renowned expert in thermal management technology, aptly stated, "Aluminum heat sinks are not just passive components; they play a pivotal role in maintaining the optimal operating temperature of electronic systems." This statement encapsulates the essence of why understanding aluminum heat sinks is vital for engineers and designers alike.

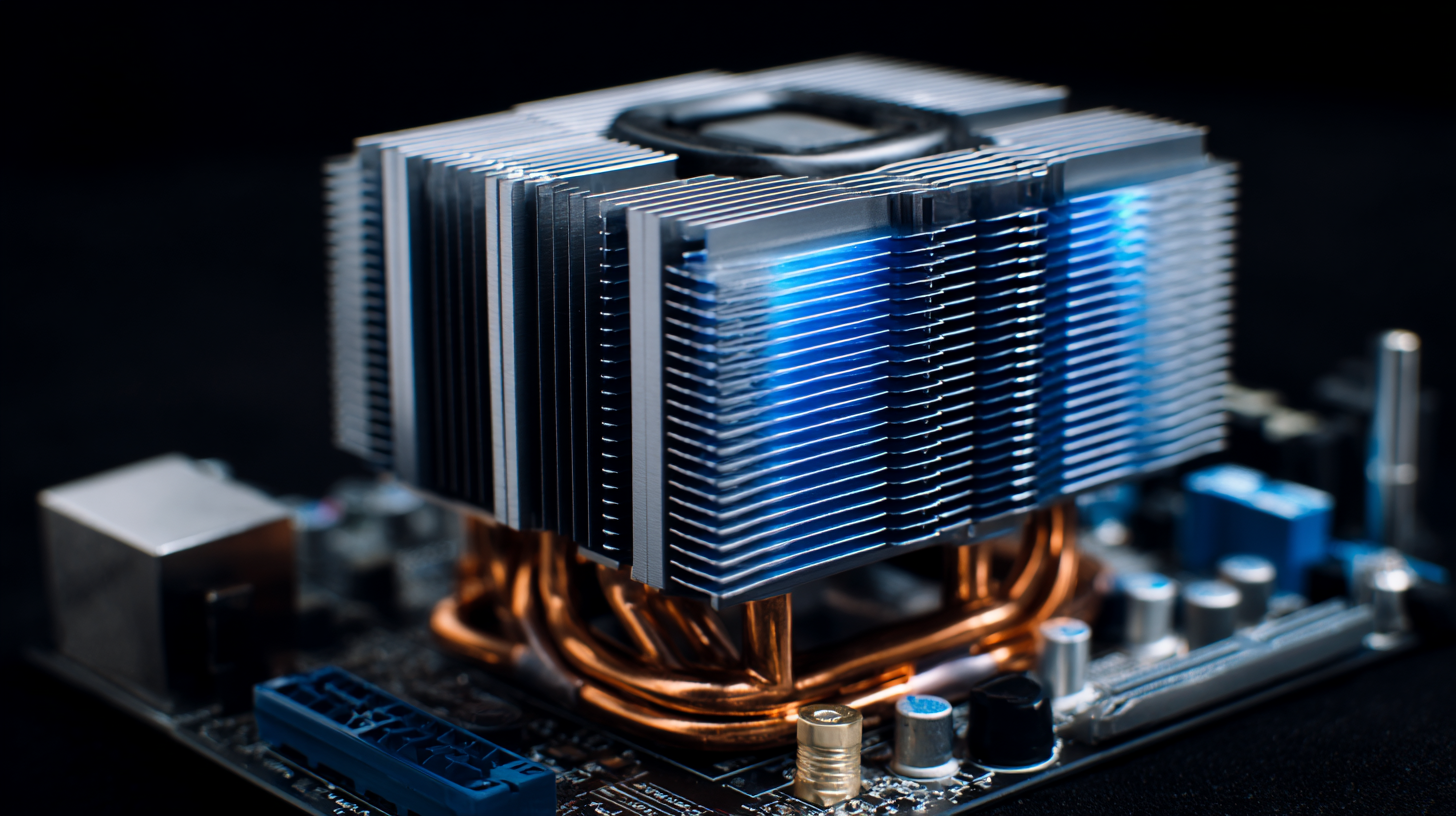

An aluminum heat sink operates on the fundamental principle of heat dissipation, absorbing heat generated by electronic components and releasing it into the surrounding air. This process is essential for preventing overheating, which can lead to system failures and reduced lifespan of the device. By leveraging the excellent thermal conductivity of aluminum, these heat sinks effectively transfer heat away from critical components, ensuring reliable and efficient operation.

As we delve deeper into the intricacies of aluminum heat sinks, we will explore their design, materials, and fundamental role in the thermal management landscape, providing a comprehensive guide for those involved in the industry.

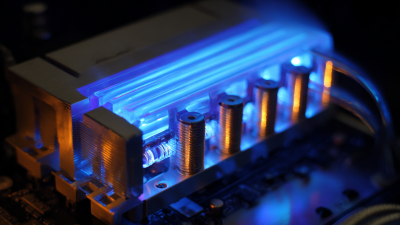

An aluminum heat sink is a crucial component in thermal management systems, especially for electronic devices that generate significant heat due to increasing power density. As technologies like 5G become more prevalent, the power output of electronic components rises, making effective heat dissipation essential. Traditional cooling methods, which often rely on passive materials, are nearing their limits due to the heightened thermal demands. In this scenario, aluminum heat sinks serve as effective passive cooling solutions, functioning by dissipating heat away from critical components to maintain optimal operating temperatures.

The role of aluminum in heat sinks is particularly notable due to its excellent thermal conductivity, lightweight nature, and cost-effectiveness. This makes aluminum an ideal choice for manufacturers seeking to enhance the performance and reliability of their products.

Market trends indicate a push towards advanced thermal management methods, integrating both passive and active cooling strategies. As new materials evolve, such as fourth-generation silicon carbide technology, the landscape of thermal management solutions will continue to adapt, ensuring that aluminum heat sinks remain a significant player in balancing efficiency and thermal stability in the ever-evolving electronics industry.

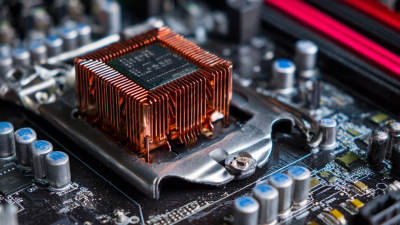

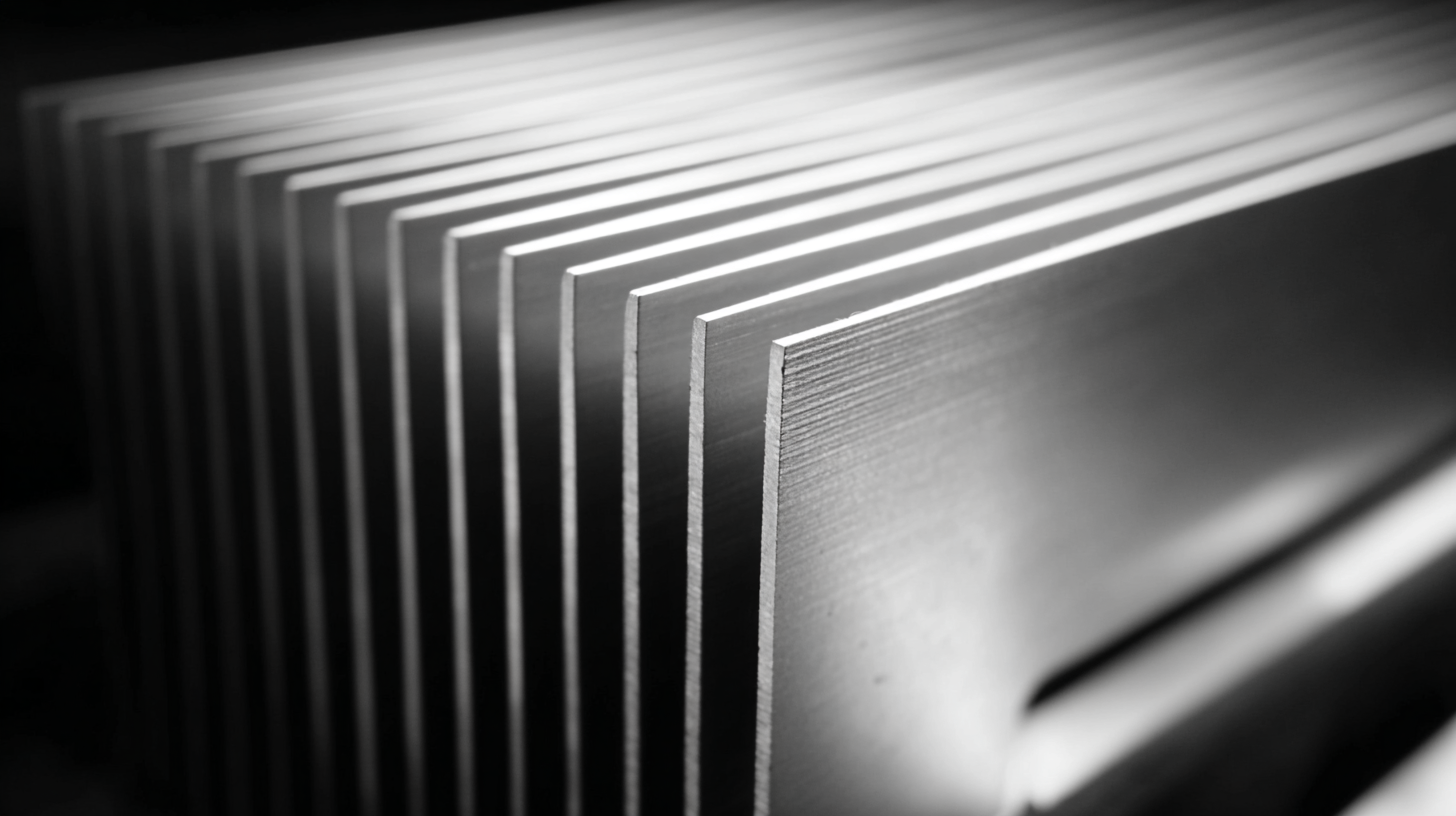

Aluminum heat sinks play a crucial role in thermal management, particularly in the electronics industry where efficient heat dissipation is essential for device performance and longevity. One of the key properties that makes aluminum an ideal material for heat sinks is its excellent thermal conductivity, which is significantly higher than that of many metals. For instance, the thermal conductivity of aluminum is about 237 W/m·K, enabling effective heat transfer away from critical components, thus maintaining optimal operating temperatures in devices.

As the electronics market continues to grow, driven by advancements in AI, 5G technology, and electric vehicles, the demand for high-performance materials like aluminum is on the rise. Reports indicate that the aluminum nitride industry, for example, has seen its market size grow from 1.34 billion RMB in 2019 to approximately 1.56 billion RMB in 2023, showcasing the increasing need for materials with superior thermal management capabilities. Furthermore, the overall market for aluminum and related composites is expected to expand, reflecting the vital role of aluminum in supporting efficient thermal management solutions across various applications.

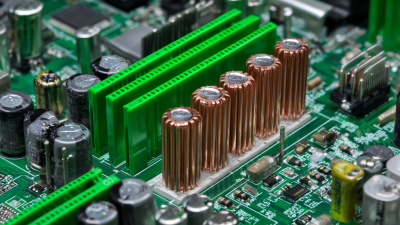

Heat sinks play a crucial role in the performance of electronic devices by efficiently dissipating heat generated during operation. When components such as CPUs and GPUs generate heat, inadequate thermal management can lead to reduced performance, shorter lifespan, and even device failure. According to a report by Frost & Sullivan, over 30% of electronic failures can be attributed to poor thermal management, emphasizing the need for effective cooling solutions in modern devices.

Aluminum heat sinks are particularly favored in the electronics industry due to their excellent thermal conductivity and lightweight properties. They enhance heat dissipation through increased surface area and better airflow, which is essential in compact designs where space is limited. A study by the Semiconductor Industry Association indicates that the global market for heat sinks is expected to grow by 10% annually over the next five years, driven by the increasing demand for high-performance electronic devices. Thus, incorporating efficient heat sinks can significantly optimize device performance, energy efficiency, and longevity.

Aluminum heat sinks are particularly favored in the electronics industry due to their excellent thermal conductivity and lightweight properties. They enhance heat dissipation through increased surface area and better airflow, which is essential in compact designs where space is limited. A study by the Semiconductor Industry Association indicates that the global market for heat sinks is expected to grow by 10% annually over the next five years, driven by the increasing demand for high-performance electronic devices. Thus, incorporating efficient heat sinks can significantly optimize device performance, energy efficiency, and longevity.

Aluminum heat sinks come in various designs, each tailored to meet specific thermal management needs across different applications. The versatility of aluminum as a material allows for the creation of extruded, folded, and stamped heat sinks, which can be engineered to maximize surface area and enhance heat dissipation. Extruded heat sinks, often used in electronics, feature fins that increase airflow and are customizable in size and shape to fit diverse devices. Meanwhile, folded heat sinks provide a lightweight solution, ideal for compact designs where weight restrictions are a concern, while also maintaining effective cooling performance.

In addition to their structural designs, aluminum heat sinks are utilized in a wide range of sectors, including automotive, telecommunications, and renewable energy. For instance, in solar panel systems, heat sinks play a crucial role in maintaining optimal operating temperatures, thus enhancing efficiency and longevity. In electronic devices, effective thermal management through well-designed heat sinks prevents overheating, ensuring reliability and performance. The variety of designs and applications illustrates the critical role aluminum heat sinks play in modern technology, highlighting their importance in effective thermal management across industries.

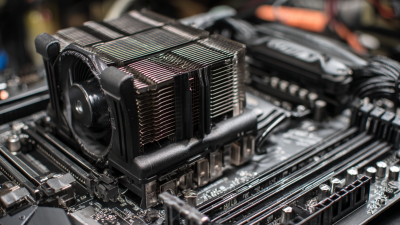

As we look towards 2025, the evolution of aluminum heat sink technology is poised to undergo significant advancements, driven by the need for more efficient thermal management solutions in various industries. Recent developments in composite materials, particularly diamond-copper combinations, are heralding a fourth-generation cooling revolution. This innovation is crucial as power densities in electronics continue to rise, demanding more effective heat dissipation methods to prevent thermal overload and enhance performance.

Market analyses project that the demand for high-performance cooling solutions, such as advanced aluminum heat sinks, will grow substantially. For instance, the latest trends indicate that industries reliant on semiconductor technology are increasingly incorporating liquid cooling systems and advanced substrate materials to enhance thermal efficiency. Additionally, the shift from 2.5D to 3D semiconductor packaging is indicative of the industry's drive for compactness and higher performance, compelling manufacturers to innovate in cooling technologies to meet tighter thermal constraints.

The upcoming 2025 Future Semiconductor Industry Innovation Conference aims to address these trends, discussing market needs and showcasing advancements in heat dissipation technologies critical for the next generation of electronic devices.