Leave Your Message

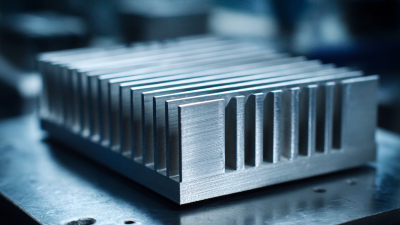

In the rapidly advancing world of electronics, effective thermal management is paramount to ensure the reliability and longevity of devices. One crucial component in achieving this is the Aluminum Heat Sink, which plays a vital role in dissipating excess heat generated by electronic components. According to Dr. Emily Carter, a leading expert in thermal management solutions, "The efficiency of heat dissipation directly impacts the performance and lifespan of electronic devices; an Aluminum Heat Sink is often the most effective solution."

As electronic devices become more compact and powerful, the need for efficient thermal solutions has never been greater. Aluminum Heat Sinks are favored for their excellent thermal conductivity, lightweight design, and cost-effectiveness, making them an indispensable element in various applications ranging from consumer electronics to high-performance computing. Their ability to maintain optimal operating temperatures not only enhances performance but also protects sensitive components from overheating, which can lead to premature failure.

In conclusion, the integration of Aluminum Heat Sinks into electronic designs is essential for effective thermal management, promoting device efficiency and longevity. As the demand for higher-performance electronics continues to rise, understanding and leveraging the capabilities of Aluminum Heat Sinks will be critical for engineers and manufacturers alike. This critical insight highlights the importance of selecting the right thermal management solutions to navigate the challenges of modern electronics.

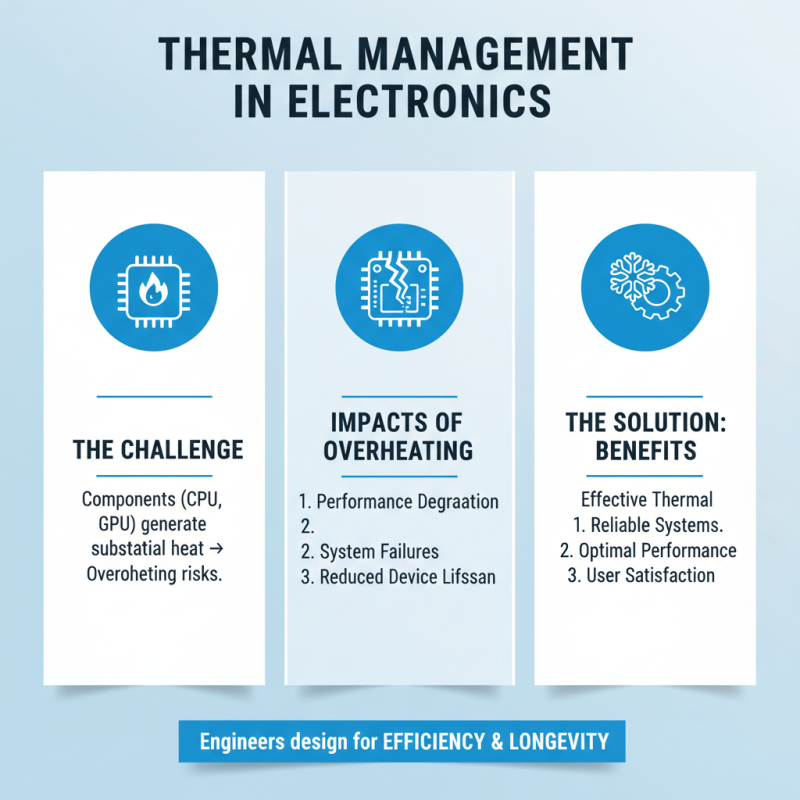

Thermal management plays a crucial role in the design and functionality of electronic devices. As components such as processors and graphics cards generate significant heat during operation, effective thermal management is necessary to prevent overheating, which can lead to performance degradation, system failures, or reduced longevity of electronic devices. Understanding the principles of thermal management allows engineers to create more reliable and efficient systems, ensuring both optimal performance and user satisfaction.

One of the key strategies in thermal management is the use of heat sinks, particularly aluminum heat sinks, which are widely favored for their excellent thermal conductivity, lightweight properties, and cost-effectiveness. These devices dissipate heat from critical components by increasing the surface area available for heat dissipation. The design of heat sinks, including their shape and size, can greatly influence their efficiency. By integrating aluminum heat sinks into electronic systems, designers can improve overall thermal performance, facilitating better heat dissipation and maintaining operational stability in increasingly compact and powerful devices.

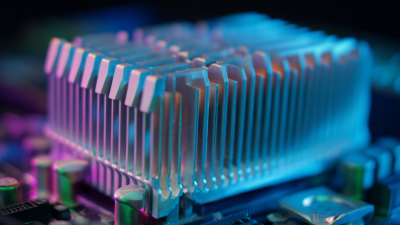

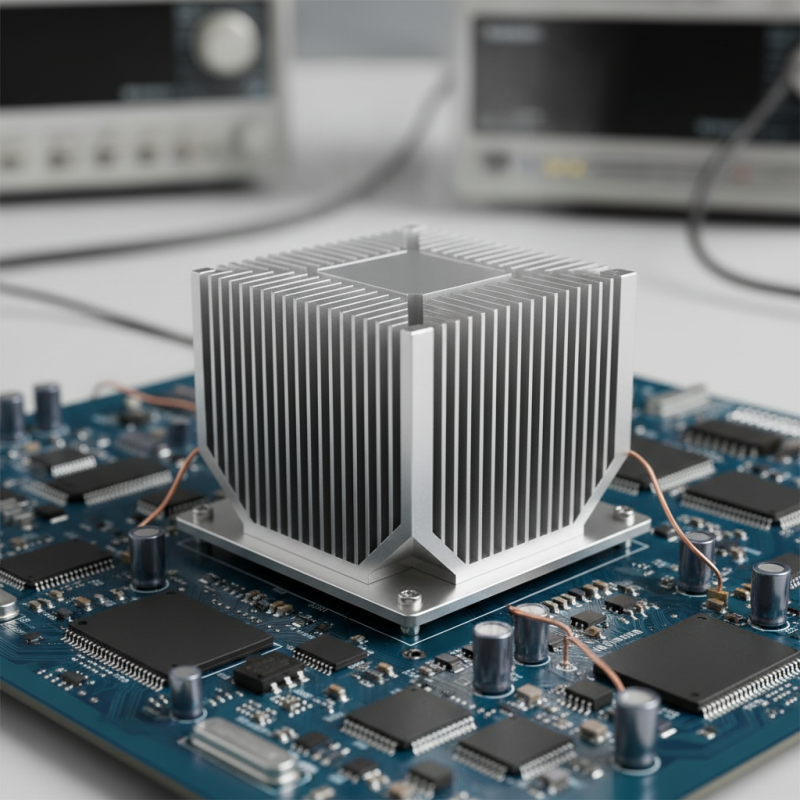

Heat sinks play a crucial role in the thermal management of electronic devices by effectively dissipating generated heat. As electronic components, such as CPUs and GPUs, operate, they generate significant amounts of heat that can lead to overheating if not properly managed. Heat sinks, typically made from materials with high thermal conductivity like aluminum, are designed to absorb this heat and release it into the surrounding environment. This process not only helps maintain optimal operating temperatures but also enhances the performance and longevity of the electronics.

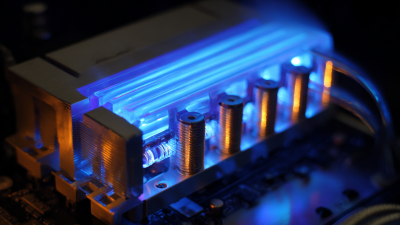

The effectiveness of a heat sink is influenced by its design, size, and surface area. A larger surface area allows for better heat dissipation as it increases contact with the air, facilitating a more effective convection process. Furthermore, heat sinks may be combined with fans to further enhance cooling performance, creating a robust cooling solution for high-powered electronic systems. By regulating temperatures, heat sinks ensure that electronic components operate within their specified ranges, ultimately minimizing the risk of thermal-related failures and improving reliability in demanding applications.

Aluminum is widely regarded as one of the most effective materials for heat sinks in electronic applications, primarily due to its excellent thermal conductivity. This property allows aluminum heat sinks to efficiently dissipate heat generated by electronic components, maintaining optimal operating temperatures and ensuring reliable performance. The high rate of thermal transfer means that aluminum can absorb heat quickly and release it into the surrounding environment, preventing overheating that could lead to component failure.

In addition to its thermal efficiency, aluminum offers superior weight and cost advantages compared to other metals. Being lightweight, aluminum heat sinks can be easily integrated into various electronic designs without adding significant bulk. Moreover, aluminum is relatively inexpensive, making it a cost-effective choice for manufacturers looking to balance performance with budget constraints. Its ease of fabrication enables intricate designs that can optimize surface area for enhanced cooling, further reinforcing aluminum's status as the material of choice in thermal management solutions for electronics.

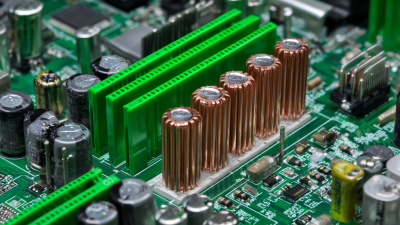

When designing effective aluminum heat sinks, several critical considerations must be addressed to optimize thermal management in electronic devices. First, the surface area of the heat sink plays a pivotal role in enhancing thermal dissipation. By increasing the surface area through fins or other geometric modifications, more heat can be released into the environment. The spacing and arrangement of these fins are equally important; they should allow for adequate airflow while minimizing resistance. Proper thermal interface materials (TIMs) are also essential, as they ensure efficient heat transfer between the heat sink and the electronic components.

In addition to geometry, the overall thermal conductivity of aluminum makes it a popular choice for heat sink materials. However, the design must also consider the specific operating conditions, such as ambient temperatures and installation environments. Factors like weight and mounting options cannot be overlooked, as they impact the overall design constraints of the electronic device. Furthermore, the finish of the aluminum can influence performance; anodizing or other surface treatments can improve corrosion resistance and enhance aesthetic appearance without compromising functionality. By carefully balancing these design elements, engineers can create aluminum heat sinks that significantly enhance the thermal management of electronic systems.

| Design Consideration | Description | Importance | Typical Applications |

|---|---|---|---|

| Material Quality | High-grade aluminum improves thermal conductivity and resistance to corrosion. | High | Computers, LED lighting |

| Surface Area | Larger surface area enhances heat dissipation. | High | Power amplifiers, automotive electronics |

| Fin Design | Optimized fin shapes and spacing improve airflow and cooling efficiency. | Medium | CPU coolers, graphics cards |

| Mounting Options | Secure mounting allows for better thermal contact and stability. | High | Industrial machines, gaming consoles |

| Thermal Interface Material (TIM) | Using high-performance TIM facilitates heat transfer between the heat source and sink. | High | Consumer electronics, telecommunications |

Aluminum heat sinks play a crucial role in the thermal management of various electronic devices by effectively dissipating heat generated during operation. In consumer electronics, such as computers and gaming consoles, aluminum heat sinks are extensively used to ensure optimal performance and longevity. By absorbing excess heat from critical components like CPUs and GPUs, these heat sinks prevent overheating, which can lead to system failures and reduced efficiency.

In telecommunications equipment, aluminum heat sinks are essential for maintaining the reliability of high-power RF amplifiers and signal processors. These components generate significant thermal output, and effective heat dissipation is vital for their functionality and operational lifespan. Similarly, in LED lighting systems, aluminum heat sinks help to manage thermal loads, enabling longer service life and enhanced luminosity. The lightweight and corrosion-resistant properties of aluminum make it a preferred choice for various applications, ensuring that devices remain cool and perform reliably under demanding conditions.