Leave Your Message

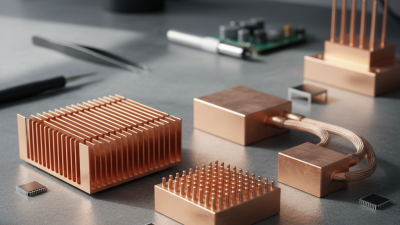

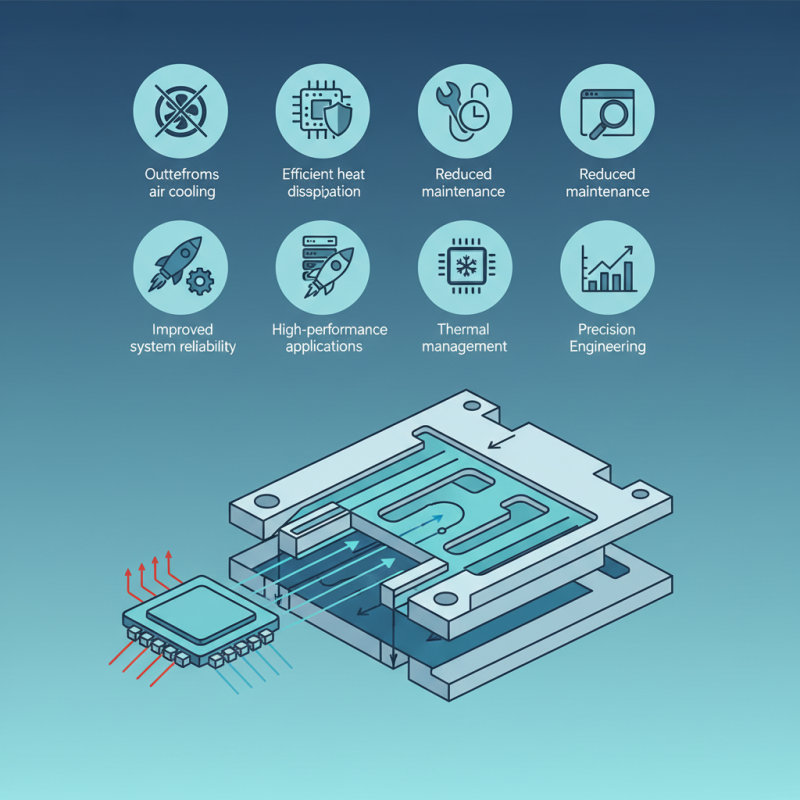

Cold Plate Cooling systems have gained significant attention in modern thermal management. According to Dr. Jane Fullerton, an expert in thermal engineering, "Cold Plate Cooling is essential for high-performance applications." These systems offer efficient heat dissipation, crucial in electronics and aerospace sectors.

Cold Plate Cooling involves the integration of liquid cooling within a plate. This method outperforms traditional air cooling techniques. However, designing effective systems is a challenge. Insufficient surface area or improper fluid dynamics can lead to inefficiencies.

Industry professionals often overlook maintenance, impacting performance. Regular checks and cleanings are necessary to avoid buildup. Cold Plate Cooling has its advantages, but careful consideration is vital. Understanding these systems can transform heat management strategies in technical fields.

Cold plate cooling systems are becoming increasingly important in various industries, including electronics and aerospace. These systems efficiently transfer heat away from critical components. According to a recent report by the International Journal of Thermal Sciences, they can reduce thermal resistance by up to 50% compared to traditional cooling methods.

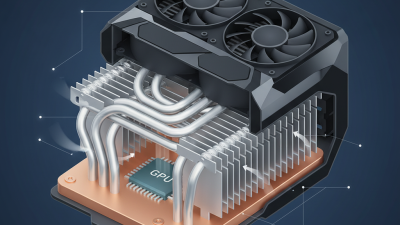

Applications for cold plates include high-performance computing and electric vehicles. In high-performance computing, they manage the heat generated by CPUs and GPUs. This is crucial, as 70% of hardware failures are due to thermal issues. Cold plates offer a direct cooling solution, improving reliability and extending the lifespan of sensitive components.

However, not all applications are suited for cold plate systems. Installation can be complex and costly. Additionally, the manufacturing process requires precision. Any error can compromise performance. There’s also the need for proper maintenance. Inadequate upkeep can lead to reduced effectiveness over time. Balancing these factors is essential for maximizing the benefits of cold plate cooling systems.

| Benefit | Description |

|---|---|

| Efficient Heat Transfer | Cold plates provide superior thermal conductivity, ensuring quick heat dissipation. |

| Space-Saving Design | Their compact design allows for installation in tight spaces without sacrificing performance. |

| Customization | Cold plates can be manufactured to meet specific thermal management requirements. |

| Reliability | They are known for their durability and long lifespan under various operational conditions. |

| Low Maintenance | Cold plates require minimal maintenance compared to other cooling systems. |

| Reduced Noise | They operate quietly, making them suitable for sound-sensitive environments. |

| Scalability | Cold plate systems can be easily scaled up for larger applications or systems. |

| Wide Application Range | They are suitable for various industries, including aerospace, electronics, and automotive. |

| Enhanced Performance | Cold plates improve the overall efficiency and performance of thermal management systems. |

| Cost-Effective | They can reduce operational costs over time due to their efficiency and low maintenance needs. |

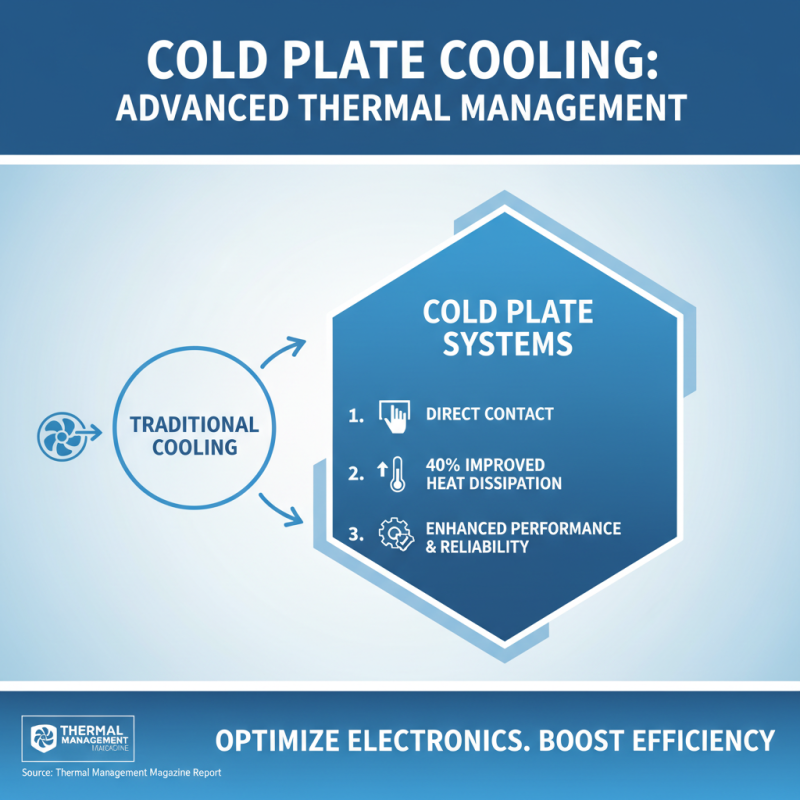

Cold plate cooling systems offer advanced thermal management compared to traditional methods. These systems utilize direct contact cooling, effectively transferring heat away from components. According to a report by Thermal Management Magazine, these systems can improve heat dissipation efficiency by up to 40%. This ability to maintain optimal temperatures enhances the performance and reliability of sensitive electronics.

One notable aspect is their design flexibility. Cold plates can be customized to fit various applications. This adaptability allows engineers to optimize thermal management in tight spaces. However, installation complexity can be an issue. Proper alignment and integration into existing systems require careful planning. A misstep in installation can lead to suboptimal performance, demonstrating the need for thorough engineering assessments.

Additionally, while cold plates excel in many areas, they rely heavily on coolant flow rates. A slow flow rate can hinder their effectiveness. In a study conducted by the Journal of Electronics Cooling, it was found that varying flow rates affected cooling performance by as much as 25%. Therefore, maintaining optimal flow is crucial. This dependence shows that cold plate systems, despite their advantages, are not a one-size-fits-all solution.

Cold plate cooling systems have gained attention for their

energy efficiency. They use a simple mechanism to absorb heat, making them effective in various applications.

With less energy consumption compared to traditional cooling methods, these systems are becoming the go-to choice for many industries.

Lower energy use translates to reduced operational costs, which can be significant over time.

Moreover, the use of cold plate systems can lead to improved performance of equipment.

By maintaining optimal temperatures, they help avoid overheating, which can decrease the lifespan of components.

This is important for manufacturers and tech companies focused on longevity and reliability.

While they do require an upfront investment, the potential savings in energy bills and maintenance costs make them a compelling option in the long run.

However, the implementation of cold plate systems is not without challenges.

The initial setup can be complex, and ongoing maintenance is necessary to ensure efficiency.

Companies must also consider the thermal management needs of their specific applications.

A one-size-fits-all approach won't work.

Understanding these nuances is crucial for truly realizing the benefits of cold plate cooling systems.

Cold plate cooling systems significantly enhance the reliability and longevity of electronic components. By efficiently dissipating heat, these systems prevent overheating. Overheating can lead to performance degradation and even failure of components. This is especially crucial in high-performance applications where consistent temperature control is necessary.

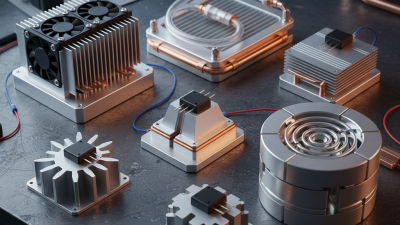

The design of cold plate systems is often tailored to specific components. Each electronic part may require unique cooling solutions. However, this customization can sometimes introduce complexity. Engineers need to assess heat loads accurately. Any miscalculation can compromise effectiveness. Regular maintenance helps ensure the cooling system operates optimally.

Investing in efficient cooling technology shows commitment to durability. Enhanced longevity means fewer replacements. Over time, this can lead to cost savings. But, it requires thoughtful planning and execution. Finding the right balance between performance and reliability is a challenge. Ultimately, the goal is a reliable system that can withstand the rigors of continuous operation.

Cold plate cooling systems offer remarkable versatility across various industries. They can be tailored to suit specific cooling requirements. From electronics to medical applications, the adaptability of these systems shines. They effectively manage heat in environments that require precision. Custom designs ensure optimal performance, accommodating different sizes and shapes of components.

The ability to customize cold plates is significant. Industries often face unique challenges in thermal management. By integrating specific materials and designs, cold plate systems can enhance efficiency. Engineers can modify dimensions, channel patterns, and connections as needed. However, finding the perfect design may require trial and error. Some designs may not provide expected performance initially. Continuous adjustments can lead to better results over time.

In applications like aerospace, reliability is crucial. Cold plate systems must perform under extreme conditions. Designers must consider factors like weight and space constraints. The need for a balance between cooling efficiency and system integrity is essential. Indecision in materials and designs can lead to compromised performance. It's important to reflect on these decisions and learn from them.