Leave Your Message

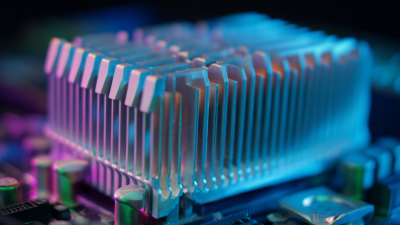

The demand for efficient thermal management solutions in electronics has escalated significantly in recent years, driven by the rapid advancement of technology and the miniaturization of electronic devices. A recent industry report highlighted that the global heat sink market is projected to grow at a CAGR of 5.8% from 2021 to 2026, underscoring the critical role of effective cooling systems in maintaining device performance and longevity. Among various materials used in heat sink manufacturing, the Copper Heat Sink stands out due to its superior thermal conductivity and performance advantages over alternatives like aluminum.

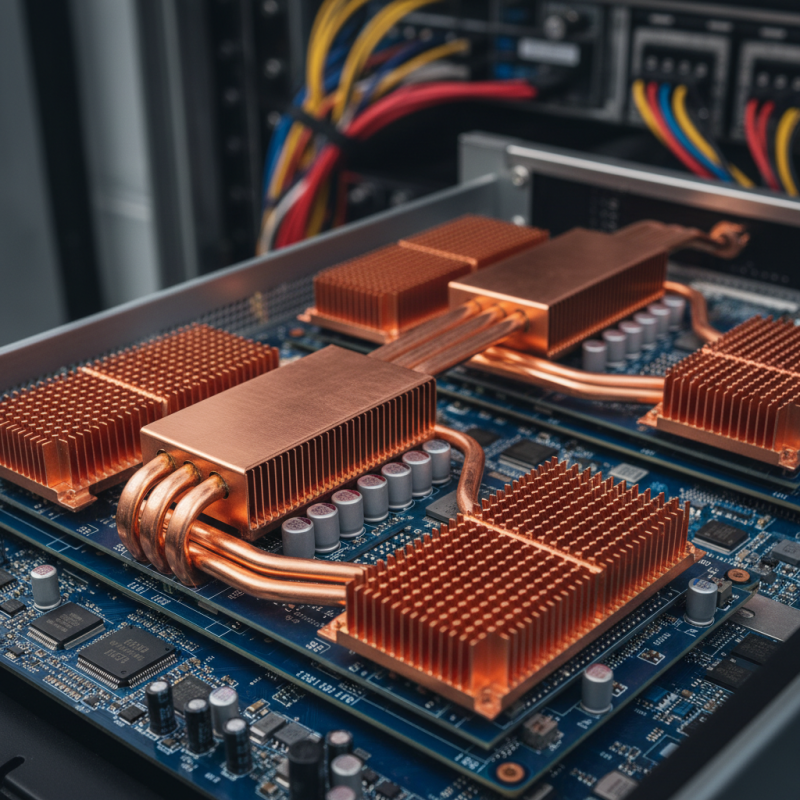

Copper, with its thermal conductivity rating of approximately 400 W/m·K, provides a significant edge in heat dissipation, making it an ideal choice for high-performance electronics where temperature control is paramount. The unique properties of Copper Heat Sinks enable them to efficiently transfer heat away from critical components, thus preventing overheating and enhancing the reliability of electronic systems. Moreover, as electronic devices become more powerful and are tasked with handling greater amounts of data, the necessity for advanced cooling solutions like Copper Heat Sinks becomes increasingly pertinent, ensuring optimal performance under intense operational conditions.

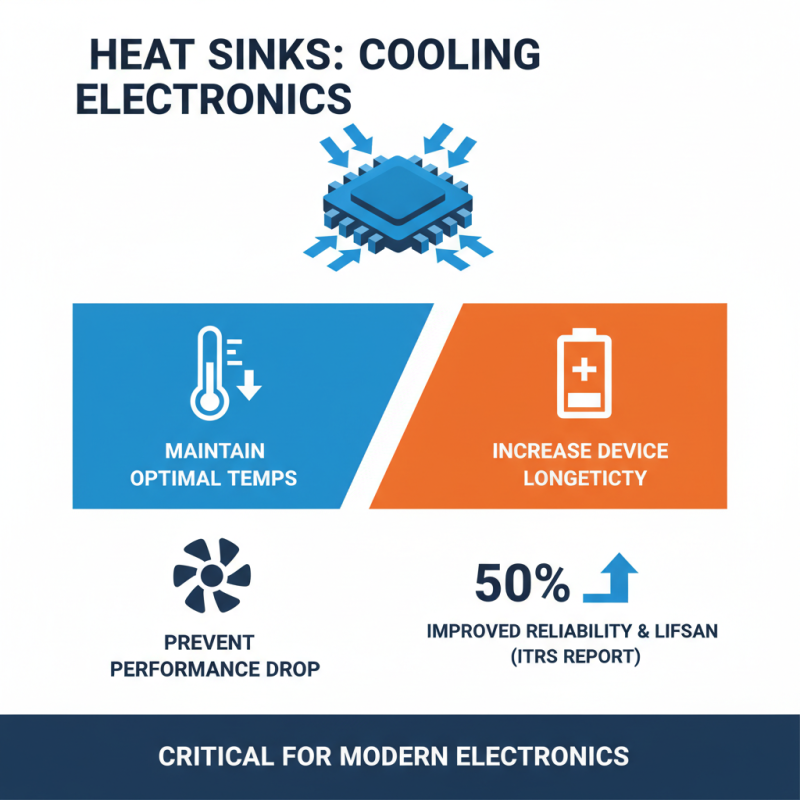

Heat sinks play a crucial role in maintaining optimal temperatures in electronic devices, where excess heat can lead to diminished performance and longevity. As semiconductor technology continues to advance, managing heat dissipation becomes increasingly critical. According to a recent report by the International Technology Roadmap for Semiconductors (ITRS), effective thermal management solutions can improve component reliability and increase the operational lifespan of devices by up to 50%. This statistic underscores the importance of heat sinks in contemporary electronics cooling strategies.

Copper heat sinks, in particular, have gained attention due to their superior thermal conductivity compared to other materials like aluminum. With a thermal conductivity of approximately 400 W/m·K, copper heat sinks can efficiently transfer heat away from critical components, ensuring they operate within safe temperature ranges. A comprehensive analysis from the Electronics Cooling magazine indicates that by using copper heat sinks, system temperatures can be reduced by 10-20°C in high-performance applications, which significantly enhances efficiency and reduces thermal throttling. As the demand for compact and powerful electronics grows, the adoption of copper heat sinks in cooling solutions is expected to rise, reflecting their importance in advancing thermal management in the industry.

Copper is widely recognized as one of the most effective materials for heat sinks in electronics due to its excellent thermal conductivity, which is approximately 400 W/m·K. This remarkable property allows for efficient heat dissipation, essential for maintaining optimal performance in electronic devices. Reports in the electronics cooling industry indicate that copper heat sinks can lead to a reduction in operating temperatures of components by up to 30%, significantly enhancing their lifespan and reliability.

Additionally, copper's ability to be easily machined and shaped into intricate designs provides engineers the flexibility to create customized heat sink structures that maximize surface area for heat transfer. According to industry studies, the thermal resistance of copper heat sinks can be up to 25% lower compared to those made from aluminum, which means that devices can operate at lower temperatures with improved energy efficiency. Furthermore, copper's natural antimicrobial properties can enhance the longevity of electronic devices in environments where hygiene is critical, making it an advantageous choice for applications ranging from consumer electronics to medical devices.

Copper heat sinks are widely recognized for their superior thermal conductivity, making them an ideal choice for efficient electronics cooling solutions. Compared to alternative materials such as aluminum, copper's thermal conductivity is significantly higher, which allows for better heat dissipation. This enhanced performance is crucial in high-power applications where overheating can lead to system failure or reduced efficiency. As electronic components generate substantial heat during operation, using copper heat sinks can help maintain optimal operating temperatures, ensuring the longevity and reliability of devices.

In addition to its superior conductivity, copper offers excellent thermal stability, which is vital for high-performance electronics. The ability of copper to withstand extreme temperatures without losing its thermal properties makes it an ideal candidate for demanding environments. Furthermore, the durability of copper ensures that heat sinks can maintain their effectiveness over time, reducing the need for frequent replacements and maintenance. This combination of enhanced thermal conductivity and stability not only improves the overall performance of electronic systems but also promotes energy efficiency, ultimately leading to cost savings in both energy consumption and component lifespan.

The cost-effectiveness of copper heat sinks in long-term applications is a critical consideration for electronics manufacturers. Copper, known for its superior thermal conductivity, allows for efficient heat dissipation, which is essential for maintaining optimal operating temperatures in electronic devices. This efficiency translates to reduced energy consumption and lower operational costs over time. Additionally, copper's durability and resistance to corrosion ensure that heat sinks maintain their performance over extended periods, further enhancing their value in long-term applications.

Tips: When selecting heat sinks for your projects, consider not only the upfront costs but also the potential energy savings over the lifespan of your devices. Investing in high-quality copper heat sinks initially can lead to significant reductions in maintenance and replacement expenses in the future.

Moreover, with the rising emphasis on sustainable practices, utilizing copper can be an eco-friendly choice. Its recyclability means that at the end of its life cycle, it can be repurposed, minimizing waste and reducing the environmental footprint. For electronics companies, this not only aligns with global sustainability goals but also adds a positive marketing angle in an increasingly eco-conscious market.

The use of copper heat sinks in electronic cooling solutions offers significant environmental benefits, primarily due to the material's recyclability and thermal efficiency. Copper is an abundant resource that can be recycled multiple times without losing its properties, making it a sustainable choice for manufacturers. By choosing copper, companies can reduce their dependency on virgin materials, ultimately minimizing the environmental impact associated with mining and processing new raw materials. This closed-loop system contributes to a more sustainable electronics industry, aligning with global goals for reducing waste and conserving resources.

Moreover, copper's superior thermal conductivity enhances the overall efficiency of electronic devices, which can lead to lower energy consumption. When devices operate efficiently, they generate less heat, reducing the need for extensive cooling systems. This decrease in energy usage contributes to a smaller carbon footprint, further supporting environmental sustainability. By investing in copper heat sinks, manufacturers not only improve the performance and longevity of their products but also actively participate in initiatives that prioritize ecological responsibility, making copper a top choice in modern electronics cooling solutions.