Leave Your Message

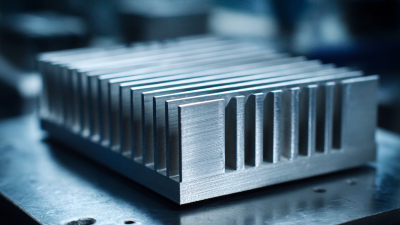

Selecting the right Transistor Heat Sink is crucial for the efficiency of electronic projects. An improperly chosen heat sink can lead to overheating, reducing the lifespan of components. According to the Thermal Management Association, nearly 60% of electronic failures are linked to inadequate heat dissipation. It’s essential to understand the thermal requirements of your transistors.

Expert Mark Thompson emphasizes, “A suitable heat sink is not just a component; it’s a critical design element.” He highlights the need for appropriate thermal conductivity and surface area. Different projects demand various heat sink types, from passive to active options. This variation can significantly impact performance.

Many engineers overlook key factors such as airflow and ambient temperature. The right Transistor Heat Sink requires more than just matching sizes; it involves a deep understanding of thermal dynamics. Often, a little extra time spent during the selection process can prevent costly mistakes later. Balancing performance and size can be challenging but rewarding, emphasizing the importance of careful consideration in the design phase.

Heat sinks play a crucial role in transistor applications. They help dissipate heat generated during operation. Proper thermal management affects device performance and longevity. In electronic designs, transistors can reach high temperatures. According to a report by the International Energy Agency, effective cooling is essential for maintaining operational efficiency. Even a slight increase in temperature can reduce performance by 10%.

In many projects, users underestimate heat sink selection. A poorly chosen heat sink may lead to thermal throttling. This can result in transient failures or even permanent damage. Research indicates that a temperature rise above 85°C can drastically shorten the lifespan of transistors. Effective heat sinks should match the power dissipation metrics of the transistor.

Choosing the right heat sink involves understanding thermal resistance ratings. The difference between the ambient temperature and junction temperature is crucial. Not all heat sinks are created equal. The material and design affect heat dissipation efficiency. Fans or thermal paste may be necessary for optimal performance. This adds complexity to the decision-making process. Lastly, as projects differ, it's essential to tailor the heat management solution to specific needs, even if that means trial and error.

| Parameter | Description | Value |

|---|---|---|

| Thermal Resistance (°C/W) | Measure of the heat sink's ability to dissipate heat | 0.5 - 5.0 |

| Material | Common materials used for heat sinks | Aluminum, Copper |

| Size (mm) | Overall dimensions of the heat sink | 25 x 25, 50 x 50, 75 x 75 |

| Weight (g) | Total weight of the heat sink | 20 - 150 |

| Mounting Type | Method of attaching the heat sink to the transistor | Clip, Screw, Adhesive |

| Application | Typical usage scenarios for the heat sink | Power Amplifiers, Switching Power Supplies |

Choosing the right heat sink for transistors is crucial for efficient thermal management. It’s easy to overlook this important component. However, understanding key factors can guide you. Start by assessing the power requirements of your transistor. The energy it dissipates directly affects heat sink size. Larger values mean more heat and, often, a bigger heat sink.

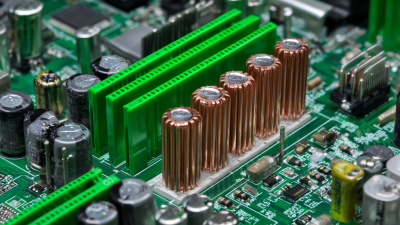

Material selection is another vital factor. Aluminum and copper are commonly used. Aluminum is lightweight and cost-effective, while copper offers better thermal conductivity. Consider your project's budget and weight constraints. Then, think about airflow. Natural convection and forced cooling can influence heat sink design. Proper airflow helps dissipate heat.

Remember to factor in the ambient temperature too. A heat sink may perform well in a lab but struggle in a warmer environment. Test under varying conditions. Trial and error may lead to the optimal choice. Each project is unique, so stay flexible. Don’t be afraid to tweak your design based on preliminary tests.

This bar chart illustrates the importance level of various factors in selecting the right heat sink for a transistor project. A higher score indicates a greater importance in the selection process.

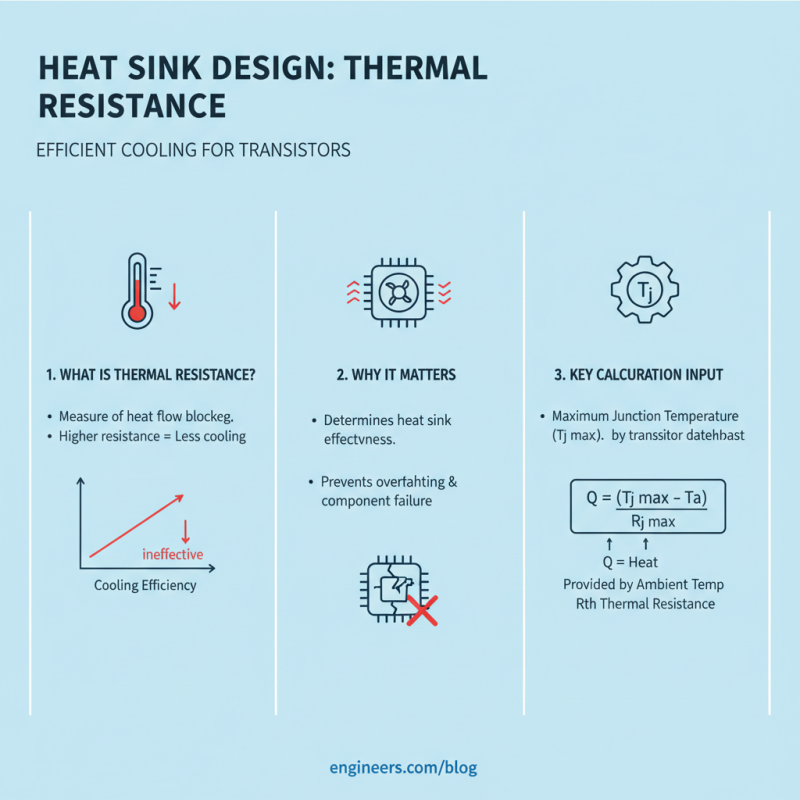

Calculating thermal resistance is essential for effective heat sink design. It determines how efficiently heat moves away from the transistor. Higher thermal resistance means less effective cooling. Engineers must know the maximum junction temperature for the transistor employed. This data is critical for calculations.

To find thermal resistance, use the formula: Rθ = (Tj - Ta) / P. Here, Tj is the maximum junction temperature, Ta is the ambient temperature, and P is the power dissipation. Understanding each variable is crucial. Many people miscalculate ambient temperature. Room temperature can vary greatly. Depending on the environment, the effective value may be different.

Heat sinks come in various shapes and sizes. A larger surface area usually means improved heat dissipation. Fins can also increase airflow around the transistor. However, it’s easy to overlook airflow in the overall design. A small fan may improve efficiency, but not everyone includes this option. Reflecting on these details is vital for successful designs. Proper thermal management is often the difference between success and failure.

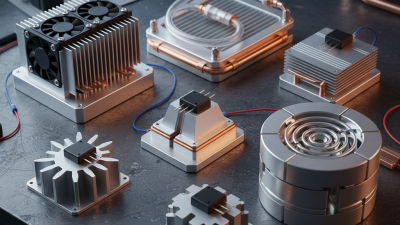

When selecting a heat sink, it's essential to understand the various types and their applications.

Extruded aluminum heat sinks are popular due to their efficiency and cost-effectiveness. They can dissipate heat at a rate of up to 100 watts per square meter.

For projects requiring more robust thermal management, forged or bonded heat sinks may be appropriate, as they provide superior contact conductance.

Natural convection heat sinks rely on airflow and can work well in low-power applications. Data suggests that around 30% of electronic devices can achieve adequate cooling using this method.

However, in high-density projects, forced convection or fan-assisted heat sinks may be necessary. These can increase cooling capacity significantly but might introduce added complexity and noise.

Another critical factor is the surface finish. A polished surface can enhance heat transfer by reducing thermal resistance, which can be crucial for high-performance applications.

However, it may not always be feasible due to budget constraints. Sometimes, practical performance may lag behind theoretical expectations.

It's vital to test and validate designs under real-world conditions for optimal outcomes.

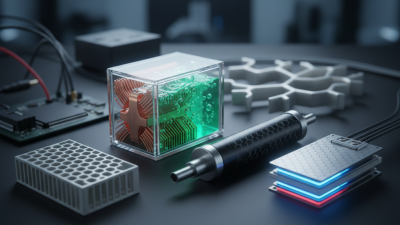

When selecting a heat sink for transistors, material choice is crucial. Aluminum and copper are popular.

Aluminum is lightweight and cost-effective. It dissipates heat moderately well, making it suitable for many applications.

However, copper excels in thermal conductivity. It transfers heat more efficiently, keeping components cooler.

The trade-off? Copper is heavier and often more expensive.

Consider how the chosen material affects your project's performance. If weight is a concern, aluminum might be the better choice.

Yet, if optimal heat dissipation is your priority, go for copper. It's essential to balance cost, weight, and performance.

In some designs, using a combination of both materials can yield better results.

Reflect on your design constraints and goals. Are you maximizing efficiency? Assess how different materials can influence your outcomes.

Sometimes, a less obvious choice can be more effective.

Don't overlook the impact of surface finish and design features. These can significantly enhance heat dissipation, regardless of the base material.