Leave Your Message

When it comes to optimizing the performance and reliability of electronic projects, selecting the right Mosfet heatsink is crucial. Mosfet heatsinks play a vital role in dissipating heat generated by power transistors, ensuring they operate within safe temperature limits. However, with the vast array of options available, making the right choice can be daunting. This essential guide aims to provide you with insightful tips and practical strategies for maximizing efficiency through informed heatsink selection. Whether you're designing a high-power circuit or refining an existing project, understanding the key factors that influence heatsink performance—such as thermal resistance, material composition, and mounting techniques—will empower you to make decisions that enhance your project's overall effectiveness. Join us as we delve into the intricacies of Mosfet heatsink selection and equip you with the knowledge to tackle thermal management challenges.

When selecting the appropriate heatsink for MOSFET devices, understanding the basic cooling requirements is critical for ensuring efficient heat dissipation. Effective thermal management is essential, especially in high-power applications where overheating can lead to performance degradation or failure. Recent advancements in phase change material (PCM) technologies have shown promise in enhancing heat transfer efficiency by absorbing and releasing heat during phase transitions, making them a viable option for improving MOSFET cooling solutions.

When selecting the appropriate heatsink for MOSFET devices, understanding the basic cooling requirements is critical for ensuring efficient heat dissipation. Effective thermal management is essential, especially in high-power applications where overheating can lead to performance degradation or failure. Recent advancements in phase change material (PCM) technologies have shown promise in enhancing heat transfer efficiency by absorbing and releasing heat during phase transitions, making them a viable option for improving MOSFET cooling solutions.

Moreover, the latest innovations in MOSFET packaging, such as top-side-cooled designs, enable better thermal performance while maintaining a compact form factor. These new packaging options are particularly beneficial for applications like electric vehicles and solar inverters, where space and efficiency are paramount. Techniques like in-situ calorimetry for measuring power loss and innovative cooling systems that minimize energy consumption are also gaining traction, underscoring the importance of integrating effective thermal management strategies to optimize the performance and longevity of MOSFETs in contemporary electronic systems.

When selecting the ideal heatsink for your MOSFET applications, several key factors must be considered to maximize efficiency. The first and foremost factor is thermal resistance, commonly quantified in degrees Celsius per watt (°C/W). According to a report by the Electronics Cooling Journal, an optimal thermal resistance value can significantly enhance the reliability and longevity of MOSFETs, ensuring they operate within their specified temperature range. A well-chosen heatsink can reduce junction temperature by up to 25°C, drastically improving performance.

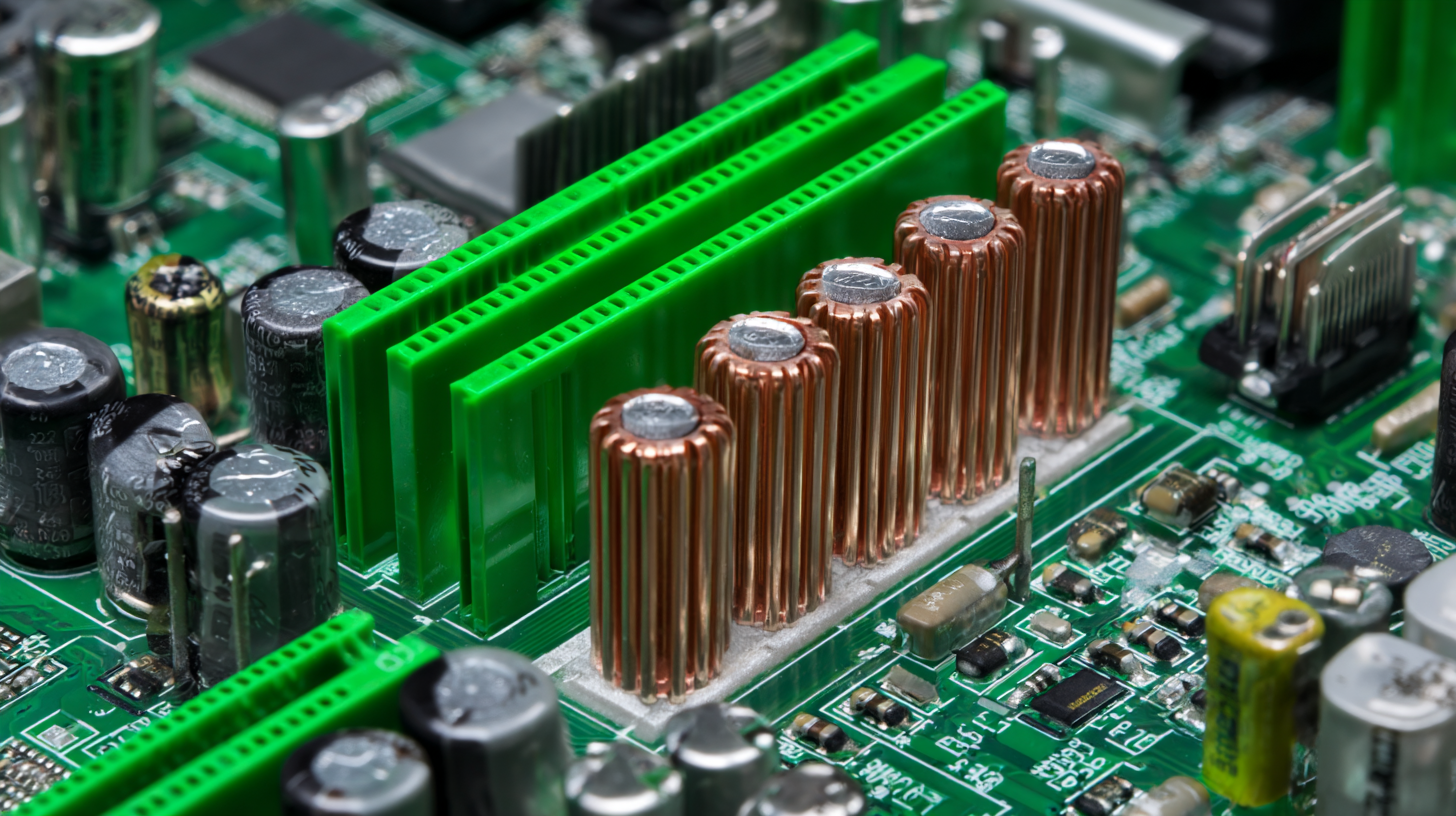

Another critical aspect is the material of the heatsink. Aluminum is often preferred due to its excellent thermal conductivity and lightweight properties, while copper heatsinks are favored in high-performance applications where efficiency is paramount. A study from the International Journal of Thermal Sciences highlighted that copper can dissipate heat 50% more effectively than aluminum under certain conditions, making it a better choice for high-power MOSFETs. Additionally, the size and surface area of the heatsink impact overall performance; larger heatsinks with fin structures promote better airflow and heat dissipation, leading to enhanced operational efficiency in your projects.

This chart illustrates the thermal resistance of different heatsink materials used for MOSFET applications. Lower thermal resistance indicates better heat dissipation, which is crucial for maximizing the efficiency of your projects.

When selecting the right heatsink for your MOSFET projects, material choice plays a pivotal role in maximizing efficiency. Recent studies have demonstrated that innovative materials, such as those utilizing phase change materials (PCMs), can significantly enhance thermal management. For instance, research on calcium nitrate tetrahydrate-based heatsinks has shown improved passive cooling capabilities for integrated circuits, showcasing how effective material strategies can optimize performance.

Tips: Consider how the thermal properties of different materials, including their ability to accommodate phase changes, can impact the cooling efficiency of your design. For applications requiring rapid thermal response, materials with solid-solid phase transitions, such as Neopentyl Glycol, may offer distinct advantages over conventional options.

Moreover, advanced designs, such as functionally graded materials, provide unique benefits in balancing thermal conductivity and structural integrity. Exploring the potential of modern approaches, including triply periodic minimal surface structures, can lead to superior thermal performance and cost-effectiveness in heatsink design. By comparing these various materials and technologies, you can make informed decisions that align with your project's requirements, ultimately leading to enhanced thermal management and improved system reliability.

| Heatsink Material | Thermal Conductivity (W/mK) | Weight (g) | Cost ($ per kg) | Corrosion Resistance |

|---|---|---|---|---|

| Aluminum | 237 | 200 | 3.00 | Moderate |

| Copper | 401 | 300 | 9.00 | Good |

| Graphite | 100-200 | 150 | 20.00 | Excellent |

| Nickel-Plated Copper | 370 | 320 | 12.00 | Very Good |

| Plastic Composites | 1-10 | 50 | 5.00 | Excellent |

When selecting a heatsink for your MOSFET, understanding the various designs available is crucial to optimizing performance. Common heatsink shapes include extruded, stamped, and folded options, each offering distinct thermal characteristics. Extruded heatsinks, with their larger surface areas, are often more effective at dissipating heat, making them ideal for high-power applications. Conversely, stamped heatsinks can be more compact, suitable for space-constrained designs, but may have limited thermal performance depending on their configuration.

Beyond the basic shapes, factors such as material and fin design significantly influence the efficiency of heat transfer. Aluminum heatsinks are popular due to their excellent thermal conductivity and lightweight properties, but copper options can provide superior thermal performance for more demanding applications. Additionally, fins that are strategically placed or designed with specific orientations can enhance airflow and increase the overall heat dissipation capabilities. Understanding these aspects not only helps in choosing the right heatsink but also ensures that your MOSFET operates within the desired thermal limits, thereby maximizing its efficiency and longevity.

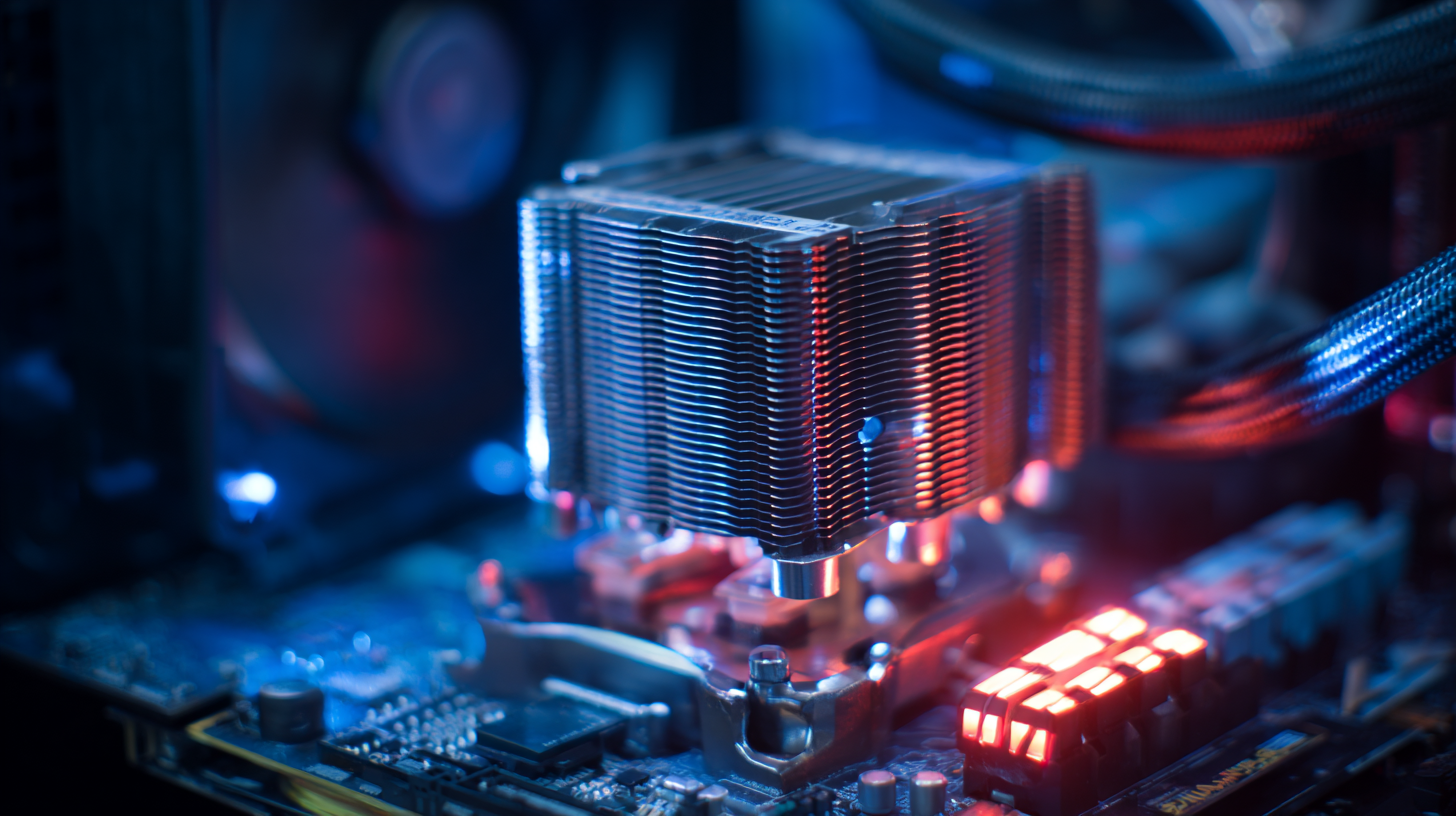

When it comes to maximizing the efficiency of MOSFETs, selecting the appropriate

heatsink is crucial. The installation of a MOSFET heatsink is not just about picking a compatible size; it also involves

understanding the thermal interface materials and ensuring proper contact between the

MOSFET and the heatsink. Using thermal paste can help eliminate air gaps, thus

improving heat transfer efficiency. Additionally, it’s essential to consider airflow

around the heatsink. Positioning the heatsink in a way that allows for adequate airflow will significantly help in

dissipating heat effectively during operation.

Regular maintenance is equally important to sustain optimal efficiency. Over time, dust

and debris can accumulate on the heatsink, diminishing its ability to dissipate heat. Routine cleaning and inspection of

both the heatsink and the associated cooling system can prevent overheating and prolong the lifespan of the MOSFET.

Furthermore, monitoring the operating temperature and ensuring it remains within

recommended limits can enhance performance. By paying attention to these installation and maintenance tips, you can ensure

that your MOSFET operates at peak efficiency, leveraging its full potential

in advanced applications like high-voltage systems.