Leave Your Message

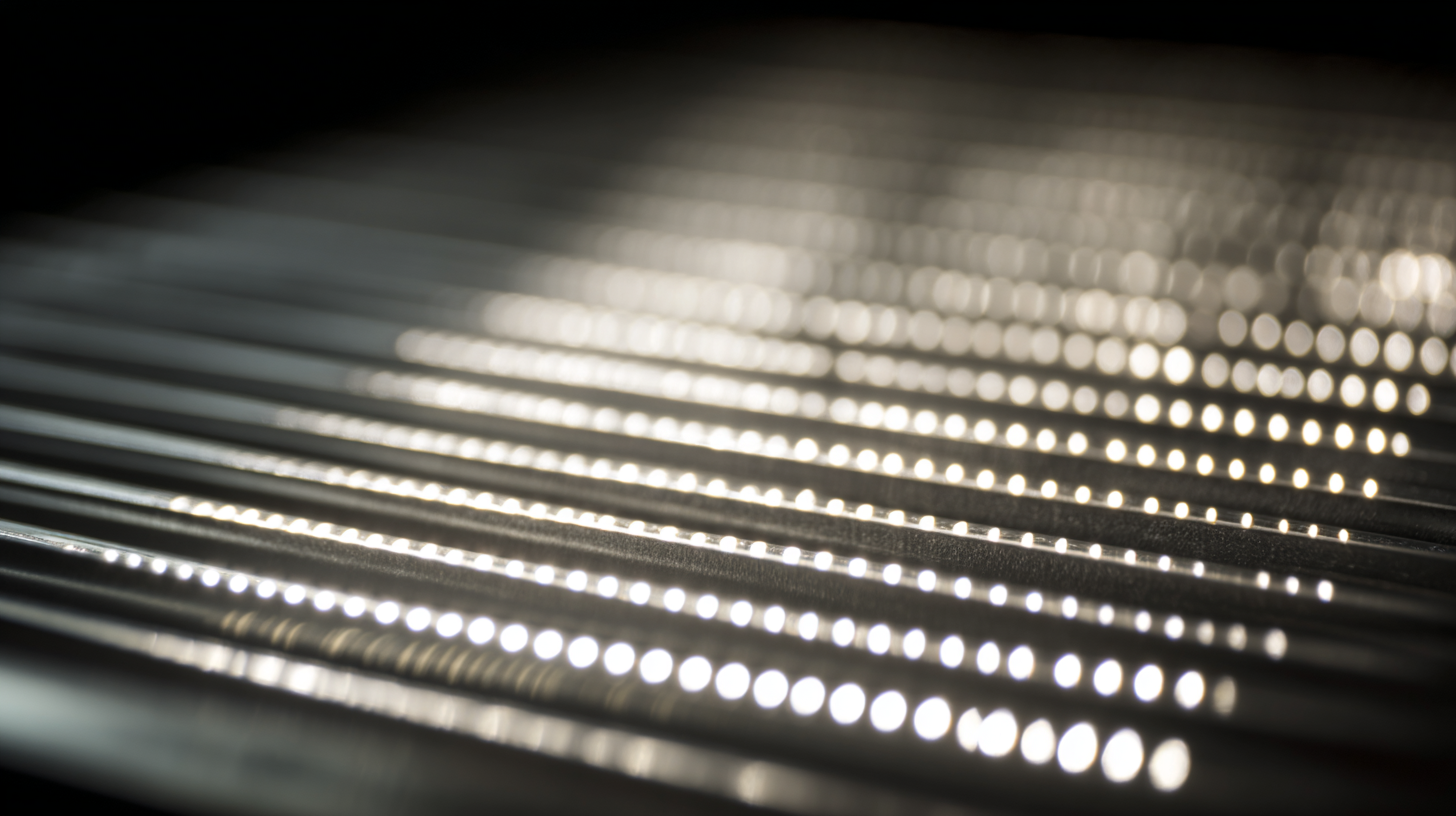

As the demand for high-efficiency lighting solutions continues to rise, understanding the role of LED heat sinks in enhancing the lifespan and efficiency of LED technology becomes imperative. According to a report by the U.S. Department of Energy, LEDs can last up to 25 times longer than traditional incandescent bulbs, yet their performance is significantly influenced by thermal management. A well-designed LED heat sink is crucial, as it dissipates heat generated by the LED, preventing overheating and potential failure. Research indicates that maintaining an appropriate operating temperature can improve luminaire efficiency by up to 20%, thereby maximizing energy savings and extending product life. By effectively utilizing heat sinks, manufacturers can ensure that their LED products not only meet but exceed industry standards, delivering superior performance and reliability in various applications.

Heat management is crucial for ensuring optimal LED performance and longevity. LEDs generate heat during operation, and excessive heat can lead to thermal degradation, significantly shortening their lifespan. Effective heat sinks are essential components that dissipate heat away from the LED chip, maintaining a stable operating temperature. This thermal regulation not only enhances efficiency by minimizing energy loss, but also prevents performance decline due to overheating.

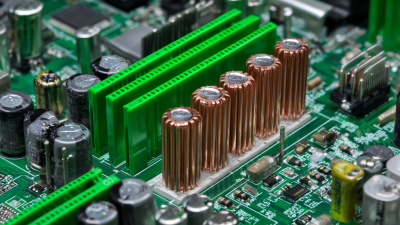

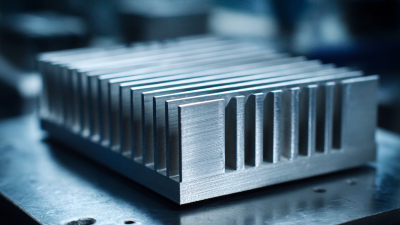

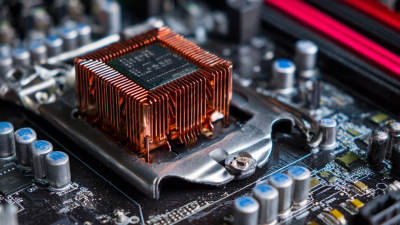

The design and material of heat sinks play a pivotal role in their effectiveness. High thermal conductivity materials, such as aluminum or copper, are commonly used to facilitate rapid heat dissipation. Furthermore, the geometry of the heat sink can influence its surface area, affecting the rate of heat transfer to the surrounding environment. By investing in a well-designed heat sink, manufacturers can ensure that LEDs operate within their ideal temperature range, thus maximizing light output and energy efficiency while extending the lifespan of the light source.

| Parameter | Description | Impact on Performance |

|---|---|---|

| Thermal Conductivity | The ability of the heat sink material to conduct heat away from the LED. | Higher thermal conductivity ensures better heat dissipation, prolonging LED lifespan. |

| Heat Dissipation Area | The surface area of the heat sink that helps in the transfer of heat to the environment. | Larger area improves airflow and lowers temperatures, enhancing efficiency. |

| Material Type | The material used for the heat sink (e.g., aluminum, copper). | Materials with high thermal properties reduce thermal resistance, increasing performance. |

| Fan Assistance | Use of fans to enhance air circulation around the heat sink. | Active cooling can significantly lower LED operating temperatures. |

| Operating Temperature | The temperature range within which the LED operates optimally. | Maintaining lower temperatures extends LED life and efficiency. |

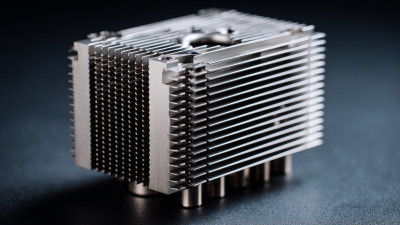

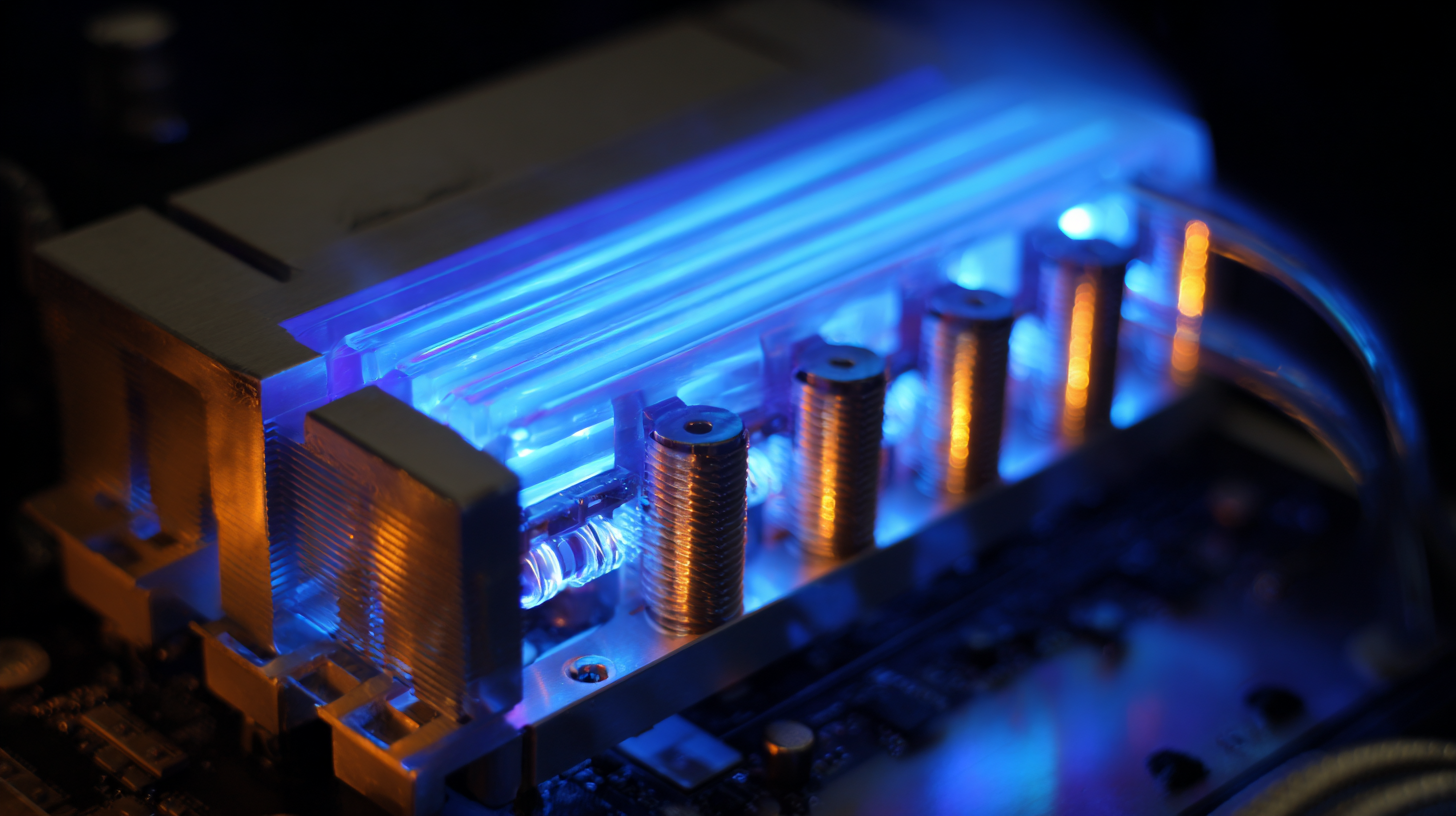

LED heat sinks play a crucial role in extending the lifespan and efficiency of LED lights by effectively managing thermal energy. A well-designed heat sink typically consists of key components such as fins, base plates, and thermal interface materials. Fins increase the surface area for heat dissipation, allowing for efficient airflow and enabling the heat to escape more rapidly. According to a report by the International Energy Agency (IEA), proper thermal management can enhance LED lifespan by up to 50%, making this component essential for long-term performance.

Moreover, base plates serve as the foundation of the heat sink, facilitating optimal contact with the LED chip and aiding in heat transfer. The choice of thermal interface materials, including thermal pastes or pads, can further enhance conductivity between the LED and the heat sink. Industry data indicates that inadequate thermal management can lead to a significant reduction in lumen output, often as much as 10-20% within the first year of use. Thus, understanding the functionality of each component in a heat sink is vital for maintaining the efficiency and reliability of LED systems, ultimately contributing to reduced energy consumption and longer replacements intervals in lighting solutions.

The impact of heat on LED lifespan and energy efficiency cannot be overstated. Elevated temperatures accelerate the degradation of LED components, leading to a decrease in their luminous output and overall performance. This is why an effective heat sink is essential in LED design. A well-engineered heat sink dissipates thermal energy, maintaining optimal operating temperatures and ultimately extending the lifespan of the LED. The integration of advanced materials and innovative cooling techniques can enhance the efficiency of heat sinks, ensuring that LEDs run cool and operate at their peak efficiency.

Tips for improving LED lifespan and efficiency include:

The design of LED heat sinks is crucial for maximizing the lifespan and efficiency of LED lighting solutions. Various materials are utilized in the construction of these heat sinks, each providing distinct advantages that contribute to thermal management. Aluminum is the most common material used due to its excellent thermal conductivity, lightweight properties, and cost-effectiveness. According to a report by the U.S. Department of Energy, properly designed aluminum heat sinks can improve LED efficiency by as much as 10-20% by maintaining optimal operating temperatures.

Another effective material is copper, known for its superior thermal conductivity compared to aluminum. While it is heavier and more expensive, copper heat sinks can effectively dissipate heat in high-wattage applications, resulting in enhanced performance. According to a recent study published in the Journal of Electronic Materials, incorporating copper into LED designs can extend the lifespan of LEDs by up to 50% when used in conjunction with proper thermal management techniques. Additionally, innovative materials such as graphite and composite heat sink designs are emerging, providing alternative solutions that balance performance and weight, catering to the design requirements of modern LED applications.

Effective thermal management is crucial for optimizing the lifespan and efficiency of LED systems. Heat sinks play a vital role in dissipating the heat generated by LEDs, as excessive heat can lead to decreased light output and a shorter operational life. Recent advancements, such as the development of plastic heat sinks, showcase innovative approaches to thermal management, challenging the traditional reliance on aluminum. These new materials offer weight savings and potentially improved thermal performance, allowing for more versatile applications in various lighting scenarios.

Effective thermal management is crucial for optimizing the lifespan and efficiency of LED systems. Heat sinks play a vital role in dissipating the heat generated by LEDs, as excessive heat can lead to decreased light output and a shorter operational life. Recent advancements, such as the development of plastic heat sinks, showcase innovative approaches to thermal management, challenging the traditional reliance on aluminum. These new materials offer weight savings and potentially improved thermal performance, allowing for more versatile applications in various lighting scenarios.

Implementing best practices for LED heat sinks involves careful consideration of design and material choices. For instance, utilizing phase change materials can enhance passive cooling, adding an extra layer of efficiency to heat sink performance. Integrating thermal simulations during the design phase can help identify optimal configurations that maximize heat dissipation. With the continuous evolution in heat sink technology, manufacturers are now better equipped to tackle the thermal challenges posed by high-performance LEDs, ensuring that lighting solutions are not only bright but also sustainable and long-lasting.