Leave Your Message

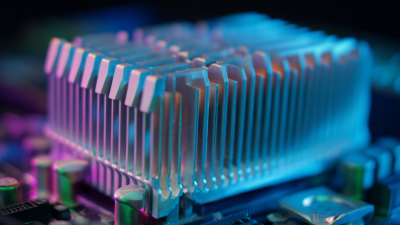

The management of thermal energy in electronic devices has become increasingly critical as the demand for higher performance and miniaturization continues to rise. Efficient thermal management solutions are essential for ensuring the reliability and longevity of electronic components. One innovative approach that has garnered attention in recent years is the use of PCM heat sinks. According to a report by the International Thermal Management Society, heat dissipation requirements in the electronics industry are projected to increase by over 30% annually, highlighting the need for advanced thermal management technologies.

PCM heat sinks leverage phase change materials (PCM) to enhance heat dissipation by absorbing and releasing thermal energy during phase transitions. Studies indicate that PCM heat sinks can significantly improve thermal conductivity and overall efficiency compared to traditional cooling methods. The utilization of PCM can result in temperature reductions of up to 20% in critical applications, which is vital for safeguarding sensitive electronic components from overheating and ensuring optimal operation.

As industries push toward greater energy efficiency and sustainability, PCM heat sinks present a promising solution that aligns with current market trends. With the increasing integration of compact and powerful electronic systems, understanding the top benefits of PCM heat sinks will be essential for engineers and manufacturers looking to optimize thermal management solutions in their designs.

Phase Change Materials (PCMs) have emerged as a game-changer in heat sink applications, offering several advantages for efficient thermal management. One of the primary benefits of using PCMs in heat sinks is their ability to absorb and release thermal energy during phase changes, which enhances temperature regulation. This capability allows systems to maintain optimal operating temperatures, reduce overheating risks, and improve overall performance, especially in high-demand environments.

Moreover, employing PCMs in heat sinks can lead to significant size and weight reductions. Traditional cooling methods often require bulky and heavy components to effectively manage heat. In contrast, PCMs can provide the same thermal management efficiency in a more compact format. This reduction in size not only makes systems lighter and more portable but also allows for more flexible designs in various applications, ranging from electronics to renewable energy systems. As industries increasingly prioritize sustainability, the energy efficiency and reduced material use associated with PCM-integrated heat sinks contribute to greener technology solutions.

Phase Change Materials (PCMs) have gained traction as an innovative solution for thermal management, particularly through their integration in heat sink designs. The significance of PCM heat sinks lies in their ability to absorb and release thermal energy effectively, maintaining optimal operating temperatures for electronic devices. By utilizing the latent heat of the PCM, these heat sinks can manage peak loads during operation, which is critical for prolonging component life and enhancing performance.

In high-performance applications, the role of PCM heat sinks becomes increasingly vital. As devices such as CPUs and GPUs generate considerable heat during heavy workloads, traditional cooling methods may fall short in addressing sudden spikes in temperature. PCM heat sinks ensure that excess heat is mitigated efficiently, effectively smoothing out temperature variations. This leads not only to improved thermal stability but also to energy savings, as devices operate more efficiently when kept within their thermal limits. Overall, the implementation of PCM heat sinks represents a forward-thinking approach to thermal management, addressing modern challenges in a variety of industries with an eye towards sustainability and enhanced efficiency.

Phase Change Material (PCM) heat sinks are gaining traction as a superior solution for thermal management compared to traditional cooling methods. Unlike conventional systems that rely on airflow or liquid cooling, PCM heat sinks utilize materials that absorb and release thermal energy during phase transitions, such as melting and solidifying. This unique property allows them to maintain a stable temperature over extended periods, providing significant advantages in scenarios requiring precise thermal regulation. According to a report by the International Journal of Thermal Sciences, PCM systems can reduce peak thermal loads by up to 30%, resulting in improved energy efficiency for electronic devices and reduced cooling system sizes.

When comparing PCM heat sinks to traditional cooling methods, it's essential to consider their overall efficiency and versatility. Traditional cooling methods often require continuous energy input to manage heat levels, whereas PCM solutions can be passively engaged, leading to reduced energy consumption. Studies have shown that PCM heat sinks can enhance thermal management performance in applications ranging from consumer electronics to outdoor environments. For instance, a comparative analysis highlighted that PCM systems can maintain operational temperature within a +/- 2°C variance, which is critical for sensitive components.

Tips: When selecting a thermal management solution, consider the specific thermal loads and space constraints of your application. Additionally, the integration of PCM heat sinks may lead to cost savings in cooling energy consumption and overall system efficiency. Regular maintenance of thermal management systems can further optimize performance, ensuring that your setup remains reliable and efficient.

Phase Change Materials (PCMs) have emerged as a revolutionary solution in the realm of thermal management, particularly due to their ability to enhance heat dissipation and improve overall system performance. By leveraging the thermal properties of PCMs, systems can effectively absorb, store, and release heat, leading to a more stable operating temperature. This phenomenon occurs as PCMs transition between solid and liquid states, enabling them to absorb excess thermal energy during peak temperatures and release it when the system cools down.

The integration of PCM heat sinks in electronic devices and industrial applications significantly optimizes thermal performance. By distributing heat more uniformly, PCM technology mitigates the risk of overheating and hotspots, which can lead to premature component failure. Furthermore, the efficient heat management facilitated by PCMs enables devices to maintain optimal performance levels with reduced energy consumption. As a result, systems can achieve longer lifespans and improved reliability, showcasing the essential role of PCMs in advancing thermal solutions in various applications.

| Benefit | Description | Impact on Performance |

|---|---|---|

| Enhanced Heat Dissipation | PCM heat sinks facilitate rapid heat transfer away from critical components. | Improves system reliability and longevity. |

| Weight Reduction | Utilizes phase change materials that are lighter than traditional metal heat sinks. | Increases portability and reduces transportation costs. |

| Temperature Regulation | Maintains a consistent temperature range during operation. | Enhances performance and prevents thermal throttling. |

| Cost Efficiency | Reduces the need for complex cooling systems. | Lower operational and maintenance costs. |

| Sustainability | Many PCM materials are environmentally friendly and recyclable. | Supports eco-friendly initiatives in product design. |

Phase Change Material (PCM) heat sinks have emerged as essential components in various industrial applications, providing efficient thermal management solutions. These materials absorb, store, and release thermal energy during phase transitions, making them invaluable in sectors that require precise temperature control. According to a recent market analysis, the global PCM market is projected to reach USD 3.5 billion by 2025, demonstrating significant uptake across industries such as electronics, automotive, and renewable energy.

In the electronics sector, PCM heat sinks are increasingly utilized in high-performance computing systems and data centers. As components generate substantial heat, traditional cooling solutions often fall short in maintaining optimal operating temperatures. PCM heat sinks can enhance thermal regulation by absorbing excess heat during peak loads and releasing it gradually, leading to improved energy efficiency and extended lifespan of critical hardware. A study indicated that implementing PCM solutions in data centers could lead to energy savings of up to 25%, showcasing their potential to revolutionize thermal management practices.

The automotive industry also benefits from PCM applications, especially in electric vehicles where efficient heat management is crucial for battery performance. By integrating PCM heat sinks, manufacturers can ensure that battery temperatures remain within safe limits during operation. Research has shown that utilizing PCM technology can lead to a reduction in battery temperature fluctuations by up to 30%, thereby enhancing battery life and safety. This alignment of thermal management with performance enhancements underscores the transformative impact of PCM heat sinks in addressing modern industrial challenges.