Leave Your Message

As the global demand for energy efficiency intensifies, innovative thermal management solutions are becoming essential across various industries. One groundbreaking development is the advent of Flexible Heat Pipes, which are poised to revolutionize how we manage and utilize thermal energy.

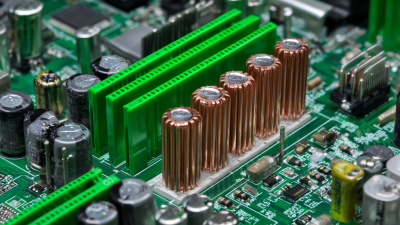

Unlike traditional rigid heat pipes, these flexible alternatives provide unmatched versatility in design and application, enabling engineers to integrate them into complex systems with ease. The ability of Flexible Heat Pipes to adapt to intricate geometries and spatial constraints opens up new opportunities for enhancing the performance of electronic devices, renewable energy systems, and industrial processes.

This evolution not only promises to enhance energy efficiency but also reduces material waste and overall operational costs. As we delve into the future of thermal management, it is clear that Flexible Heat Pipes are at the forefront of transforming energy solutions for a sustainable world.

Unlike traditional rigid heat pipes, these flexible alternatives provide unmatched versatility in design and application, enabling engineers to integrate them into complex systems with ease. The ability of Flexible Heat Pipes to adapt to intricate geometries and spatial constraints opens up new opportunities for enhancing the performance of electronic devices, renewable energy systems, and industrial processes.

This evolution not only promises to enhance energy efficiency but also reduces material waste and overall operational costs. As we delve into the future of thermal management, it is clear that Flexible Heat Pipes are at the forefront of transforming energy solutions for a sustainable world.

Flexible heat pipes are emerging as a game-changing technology in modern thermal management solutions, providing enhanced energy efficiency across various applications. Their unique design allows for a lightweight and adaptable approach to heat transfer, making them ideal for integration in spaces where traditional thermal management systems may fall short. As industries increasingly recognize the importance of efficient thermal management, flexible heat pipes are becoming integral in fields such as data centers, automotive, and consumer electronics.

Flexible heat pipes are emerging as a game-changing technology in modern thermal management solutions, providing enhanced energy efficiency across various applications. Their unique design allows for a lightweight and adaptable approach to heat transfer, making them ideal for integration in spaces where traditional thermal management systems may fall short. As industries increasingly recognize the importance of efficient thermal management, flexible heat pipes are becoming integral in fields such as data centers, automotive, and consumer electronics.

The growing emphasis on energy efficiency has propelled the demand for advanced thermal management systems, with market projections indicating significant growth. This evolution is partly driven by the robust expansion of the data center insulation market, projected to reach USD 1.61 billion by 2032. Flexible heat pipes not only optimize heat dissipation but also contribute to the overall longevity and performance of electronic systems, reinforcing their value in maintaining optimal operating conditions in high-performance environments. With the continuous advancement of technology, flexible heat pipes will likely play a pivotal role in shaping the future landscape of thermal management solutions.

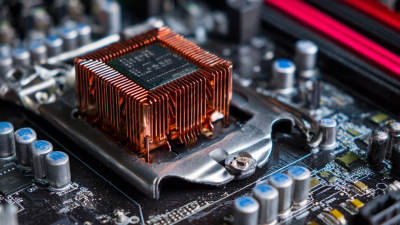

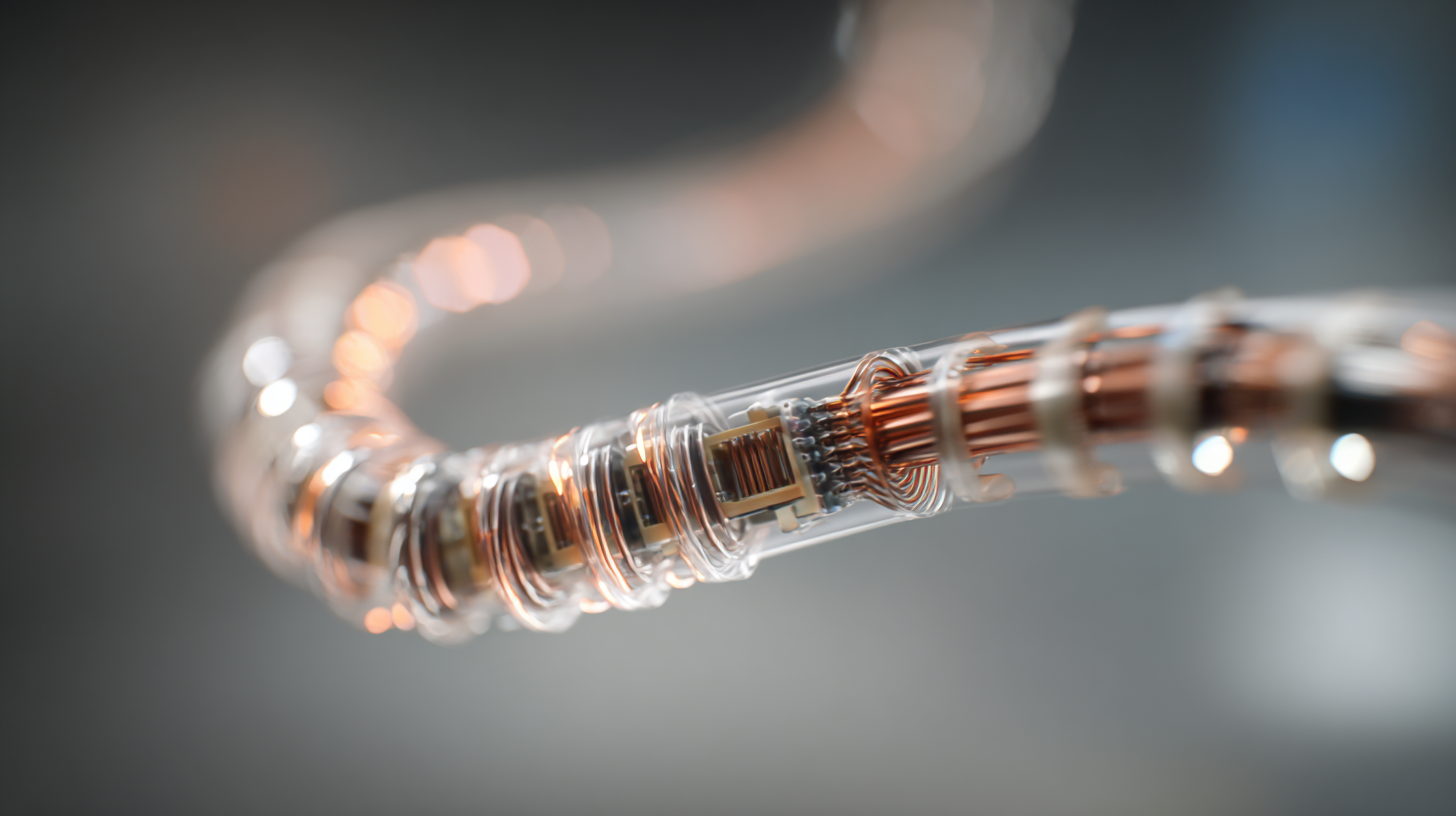

The evolution of flexible heat pipes is significantly driven by innovative materials that enhance energy efficiency across various applications. With advancements in thermal management, materials such as cross-linked polyethylene have emerged as integral components in modern piping systems. These materials not only reduce heat loss but also contribute to the overall effectiveness of thermal insulation, making them vital in sectors like construction and aerospace. The integration of such materials into flexible heat pipes allows for a more efficient transfer of heat, ultimately leading to energy savings and improved performance.

Additionally, the introduction of cutting-edge materials like graphene showcases the potential for even greater advancements in thermal management technologies. Graphene's unique properties, including high thermal and electrical conductivity, open the door for the development of flexible heat pipes that are both more efficient and lightweight. This shift towards utilizing innovative materials not only enhances the functionality of thermal management systems but also aligns with the growing demand for sustainable and energy-efficient solutions in today's modern landscape.

This bar chart illustrates the thermal conductivity of various materials used in flexible heat pipes. The goal is to showcase how innovative materials are enhancing the energy efficiency of thermal management systems. As we can see, graphene stands out as a superior thermal conductor compared to traditional materials like copper and aluminum.

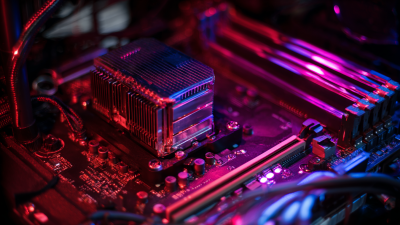

The recent advancements in thermal management through the development of flexible heat pipes are significantly impacting energy efficiency across various sectors. These innovative heat pipes enhance thermal conductivity while maintaining a lightweight, flexible profile, allowing for greater integration within sustainable technologies. This improved energy efficiency not only reduces energy consumption but also minimizes carbon footprints, supporting the transition toward greener solutions.

Tips for leveraging enhanced energy efficiency include focusing on the design of products to incorporate flexible heat pipes, thereby improving heat dissipation in devices like electric vehicles and renewable energy systems. Additionally, regular maintenance and monitoring of thermal systems can ensure optimal performance and longevity, furthering the impact of sustainable technologies.

As industries embrace these advancements, consumers should also consider energy-efficient products that utilize flexible heat pipes, ensuring that their choices contribute to a more sustainable future. By being proactive in selecting energy-efficient technologies, both individuals and organizations can play a crucial role in promoting sustainability and reducing environmental impact.

| Technology | Efficiency Improvement (%) | Thermal Conductivity (W/mK) | Sustainability Impact (Rating 1-5) | Application Area |

|---|---|---|---|---|

| Flexible Heat Pipe Technology | 25% | 400 | 4 | Renewable Energy Systems |

| Phase Change Materials | 30% | 250 | 3 | Building Insulation |

| Heat Exchangers | 20% | 300 | 5 | Industrial Processes |

| Thermal Interface Materials | 15% | 150 | 4 | Electronics Cooling |

| Nanofluids | 35% | 500 | 5 | Cooling Systems |

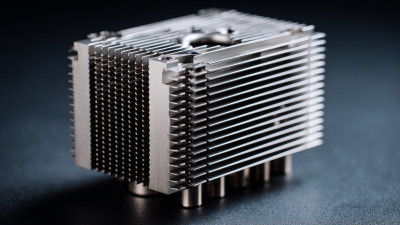

The implementation of flexible heat pipes presents both opportunities and challenges, particularly in the field of thermal management for electronic devices. Recent innovations, such as adaptable two-phase thermal circulation systems, showcase the potential for heat pipes that conform to complex geometries, allowing for enhanced cooling in space-constrained environments. However, the design and fabrication of such systems must contend with issues of seal integrity and reliability, especially when employed in demanding applications. A review highlighted that factors affecting the seal integrity in heat sealed packaging could echo the challenges faced in ensuring the durability of flexible heat pipes.

Moreover, the evolution of ultra-thin heat pipes coincides with the increasing demand for energy-efficient solutions in portable electronics. As per industry reports, advancements in micro-groove technology have resulted in significant enhancements in thermal management efficiency, making these components indispensable for high-power applications. However, the transition to these advanced heat pipes necessitates a deep understanding of material properties and limitations, which could hinder widespread adoption. Overcoming these obstacles will be crucial for the integration of flexible heat pipes into the future landscape of energy-efficient technologies.

The future of thermal management systems is being significantly influenced by the advancements in flexible heat pipe technology, which is proving to be a game changer for energy efficiency. With the rapid growth of the electric vehicle (EV) market projected to see the market size of battery packs rise from $253.3 million in 2024 to $1.876 billion by 2032, there is an increasing emphasis on rethinking heat management strategies to accommodate the shift from traditional internal combustion engines to electric powertrains. The integration of new components, such as battery cooling systems and electric drive units, requires a comprehensive redesign of thermal management frameworks, guiding innovations from conventional air-conditioning methods to more efficient heat pump technologies.

As electric vehicles become more prevalent, the automotive industry's focus will pivot towards optimizing energy consumption and enhancing performance through advanced thermal systems. The upcoming 2024 Chinese Automotive Thermal Systems Academic Annual Conference in Xi'an will serve as a significant platform for discussing these trends. Experts will convene to explore the latest developments in thermal management, particularly in relation to the "four modernizations" that drive the transformation of energy systems in the context of carbon neutrality. This evolution is crucial for ensuring the sustainability and reliability of electric vehicles while addressing the increasing demands placed on their thermal management architectures.