Leave Your Message

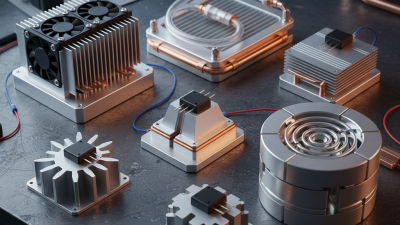

In the ever-evolving landscape of technology, maintaining optimum thermal management is crucial, particularly in high-performance computing and electronic devices. The significance of effective Cooling Heat Sink solutions cannot be overstated, as they play a pivotal role in ensuring device longevity and efficiency.

Dr. Emily Chang, a leading expert in thermal management systems at the Institute of Thermal Science, has stated, “In the pursuit of higher performance, innovative Cooling Heat Sink designs are not just beneficial; they are essential for the future of electronics.”

As we look toward 2025, the possibilities for advancements in Cooling Heat Sink innovations are boundless. The industry is witnessing a surge in creative solutions that emphasize both functionality and sustainability. From phase change materials to advanced geometries that enhance airflow, the latest developments promise not only to improve cooling efficiency but also to reduce energy consumption significantly.

In this article, we will explore the top ten Cooling Heat Sink innovations set to shape the future of thermal management. Each innovation highlights an aspect of ingenuity, driven by the relentless quest for enhanced performance and reliability in electronic applications. With experts across the globe working tirelessly to push the boundaries of thermal technologies, the Cooling Heat Sink industry is poised for a revolutionary transformation.

In recent years, thermal management solutions have become increasingly vital, especially as electronic devices become more compact and power-dense. According to a report by MarketsandMarkets, the global thermal management market is projected to reach $19.37 billion by 2025, growing at a CAGR of 8.6%. This growth highlights the accelerating need for efficient heat dissipation strategies across various sectors, including consumer electronics, automotive, and telecommunications.

Emerging trends in thermal management focus on innovative materials and technologies designed to enhance heat sink performance. For instance, the use of graphenes and phase change materials (PCMs) has gained traction due to their superior thermal conductivity and heat storage capabilities. A study by IDTechEx suggests that integrating PCMs can improve heat dissipation efficiency by up to 30%, significantly enhancing the longevity and reliability of electronic components. As manufacturers strive for higher thermal efficiency, we are likely to witness the adoption of advanced computational fluid dynamics (CFD) tools, enabling more precise and optimized designs for cooling solutions, catering to the evolving demands of modern electronics.

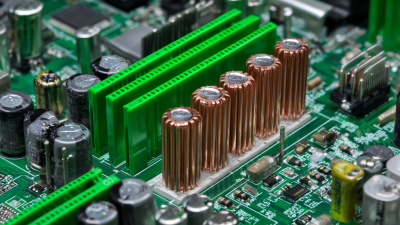

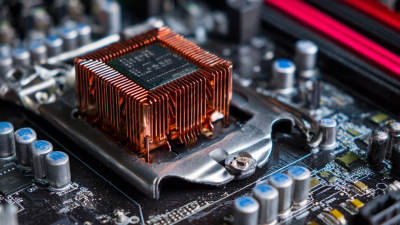

The design of heat sinks is rapidly evolving, particularly with the incorporation of advanced materials such as graphene and metal matrix composites. Graphene, known for its exceptional thermal conductivity, can significantly enhance the performance of heat sinks when combined with metals. Recent developments indicate that the integration of highly aligned graphene networks into copper composites can lead to largely improved thermal conductivity. This innovation highlights a promising pathway for creating more efficient thermal management solutions in densely packed electronic systems.

In addition to graphene, metal matrix composites are emerging as a versatile option for heat sink designs. These composites can be tailored to meet specific thermal and mechanical requirements, thus addressing the challenges posed by modern electronic devices. With the continuous miniaturization of electronic components, the demand for advanced packaging materials and effective thermal interface solutions is crucial. As research progresses in optimizing material interfaces and enhancing bonding techniques, we can expect next-generation heat sinks to reliably support power electronics, ensuring enhanced performance and prolonged device lifespan.

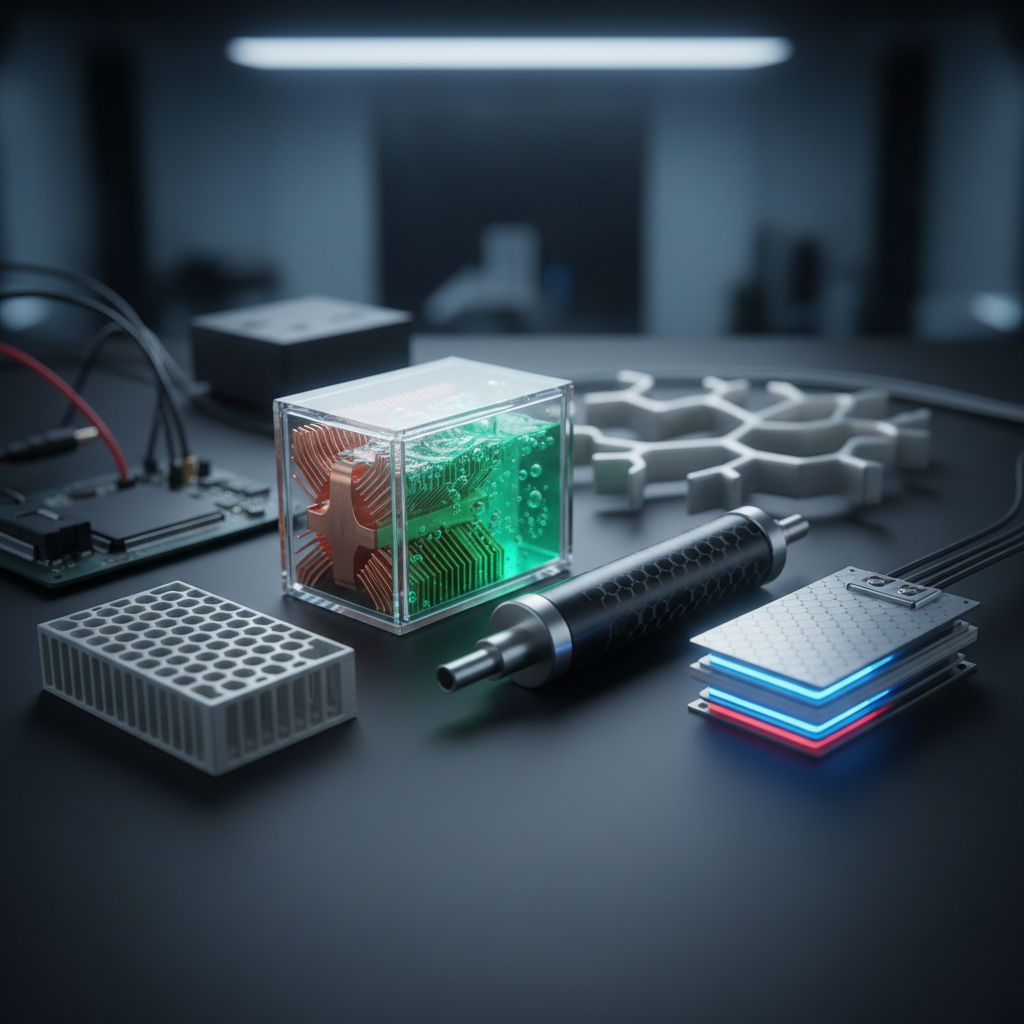

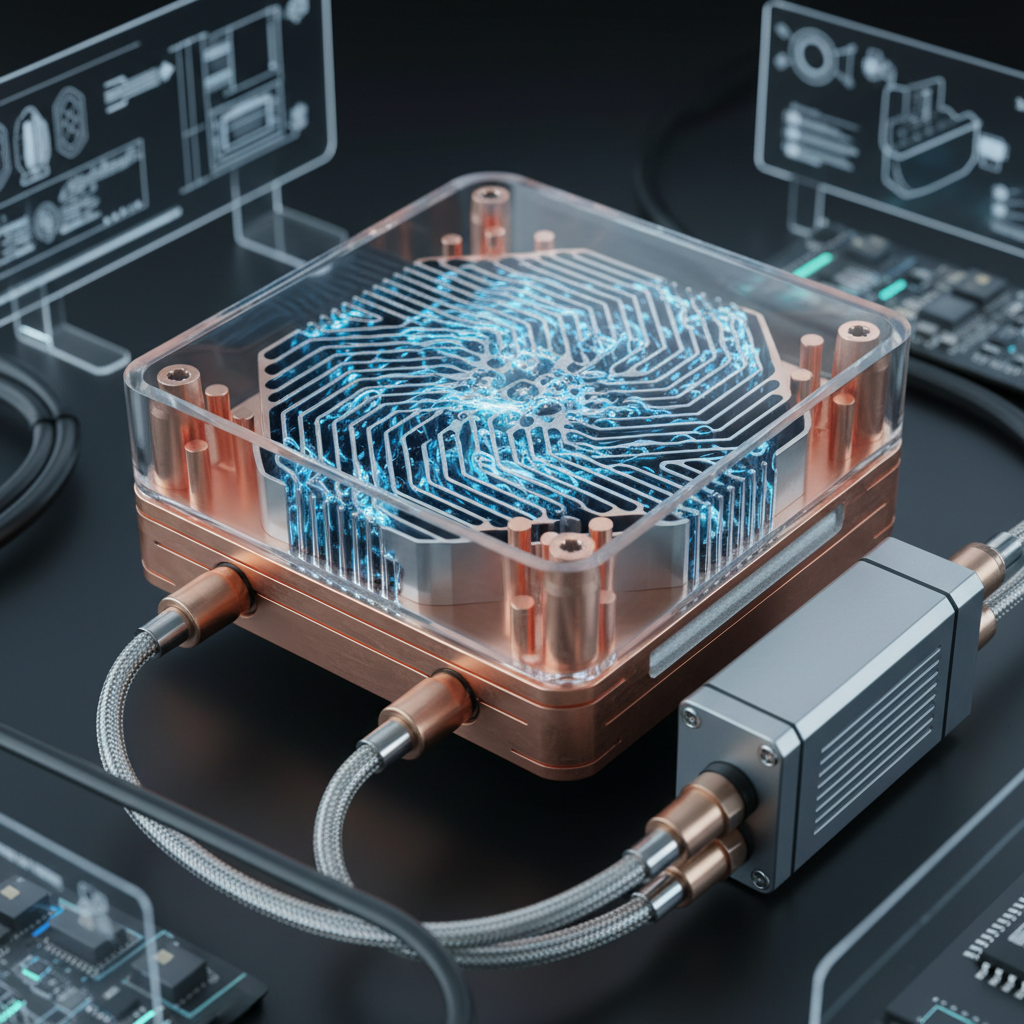

Innovative microchannel heat sink designs are transforming the landscape of thermal management in various applications, from electronics to automotive engineering. These advanced cooling solutions leverage the principles of fluid dynamics and heat transfer to achieve superior thermal performance in compact spaces. By utilizing a series of miniature channels, these heat sinks increase the surface area available for heat dissipation while simultaneously enhancing the fluid flow, resulting in efficient cooling even under high heat loads.

Recent developments in microchannel technology have focused on materials and geometries that optimize thermal conduction and reduce pressure drop. For instance, the integration of novel nanostructured surfaces can significantly improve heat transfer coefficients. Additionally, designs that incorporate variable channel widths allow for adaptability to different thermal loads, making these heat sinks highly relevant for next-generation electronics that demand higher performance and reliability. As industries strive for increased energy efficiency and miniaturization, microchannel heat sinks represent a pivotal advancement, poised to meet the cooling challenges of the future.

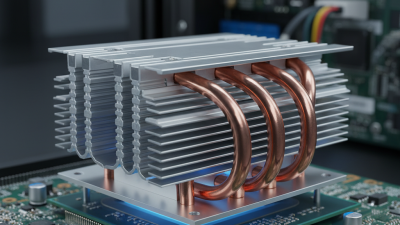

As the demand for more efficient thermal management solutions grows, adaptive heat sinks have emerged as a critical innovation in modern electronics. These smart technologies are designed to dynamically respond to varying thermal loads, enhancing performance and prolonging the lifespan of electronic components. By utilizing advanced materials and embedded sensors, adaptive heat sinks can monitor temperature fluctuations in real-time, adjusting their thermal conductivity and airflow accordingly. This not only optimizes cooling efficiency but also minimizes energy consumption, making them an ideal choice for high-performance applications in computing, automotive, and consumer electronics.

Moreover, the integration of smart technologies into heat sink design enables manufacturers to implement predictive maintenance protocols. By analyzing data collected from temperature sensors, these adaptive systems can predict potential overheating situations before they occur, prompting automatic adjustments or alerts to prevent failures. As the electronics landscape continues to evolve with the rise of IoT devices and AI applications, the need for scalable and intelligent thermal management solutions becomes increasingly vital.

Ultimately, adaptive heat sinks represent a promising frontier in the quest for more sustainable and reliable electronics, setting the stage for innovations in how we manage heat in technology-rich environments.

The pursuit of sustainability in heat sink production is becoming increasingly vital as the electronics industry intensifies its focus on eco-friendly practices. One of the most promising innovations is the use of biodegradable materials, such as natural fibers and bioplastics, which reduce environmental impact without compromising performance. These materials are not only lightweight but can be engineered to provide effective thermal management, allowing for a smooth transition from traditional metals to greener alternatives.

Additionally, advancements in manufacturing processes are reshaping the heat sink landscape. Techniques like 3D printing and additive manufacturing enable the creation of complex geometries that enhance heat dissipation while minimizing material waste. These processes can also incorporate recycled materials, further reducing the carbon footprint. By investing in sustainable practices, companies are not only addressing regulatory pressures but also responding to consumer demand for environmentally responsible products, making sustainability a cornerstone of future heat sink innovations.