Leave Your Message

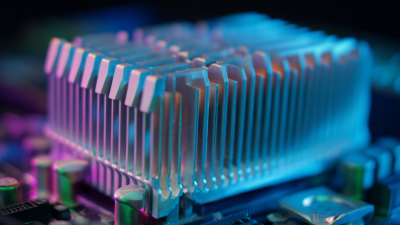

In the realm of electronics, effective thermal management is crucial to ensure optimal performance and longevity of components, particularly for transistors. Transistor Heat Sink solutions play an essential role in dissipating excess heat generated during operation, thus maintaining operational efficiency and preventing thermal runaway. According to a recent report by the Electronics Cooling Journal, inadequate thermal management can lead to a 50% reduction in the lifespan of electronic devices, highlighting the importance of selecting the right heat sink.

As the demand for high-performance electronics continues to surge, driven by trends in automation and IoT, the design and selection of Transistor Heat Sinks become increasingly critical. Research by Industry Research Firm projects that the global heat sink market will reach $3.0 billion by 2025, underscoring an urgent need for innovative cooling solutions.

In this article, we will explore the top seven Transistor Heat Sink solutions available today, focusing on their design efficiency, material selection, and compatibility with various transistor types, ensuring that engineers and designers can make informed decisions for optimal thermal performance.

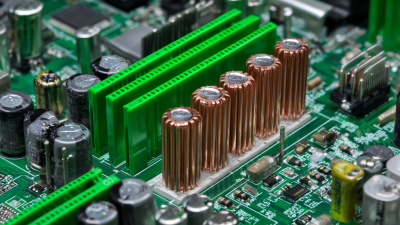

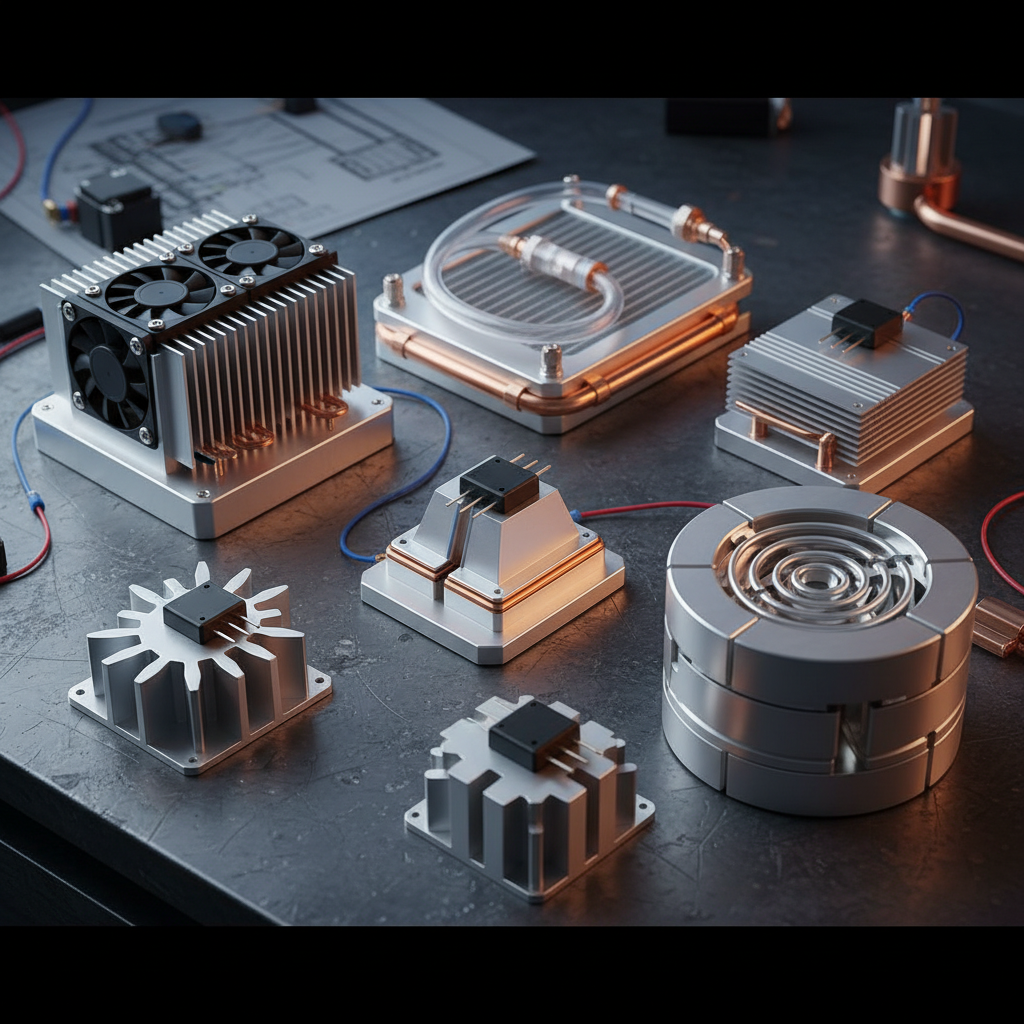

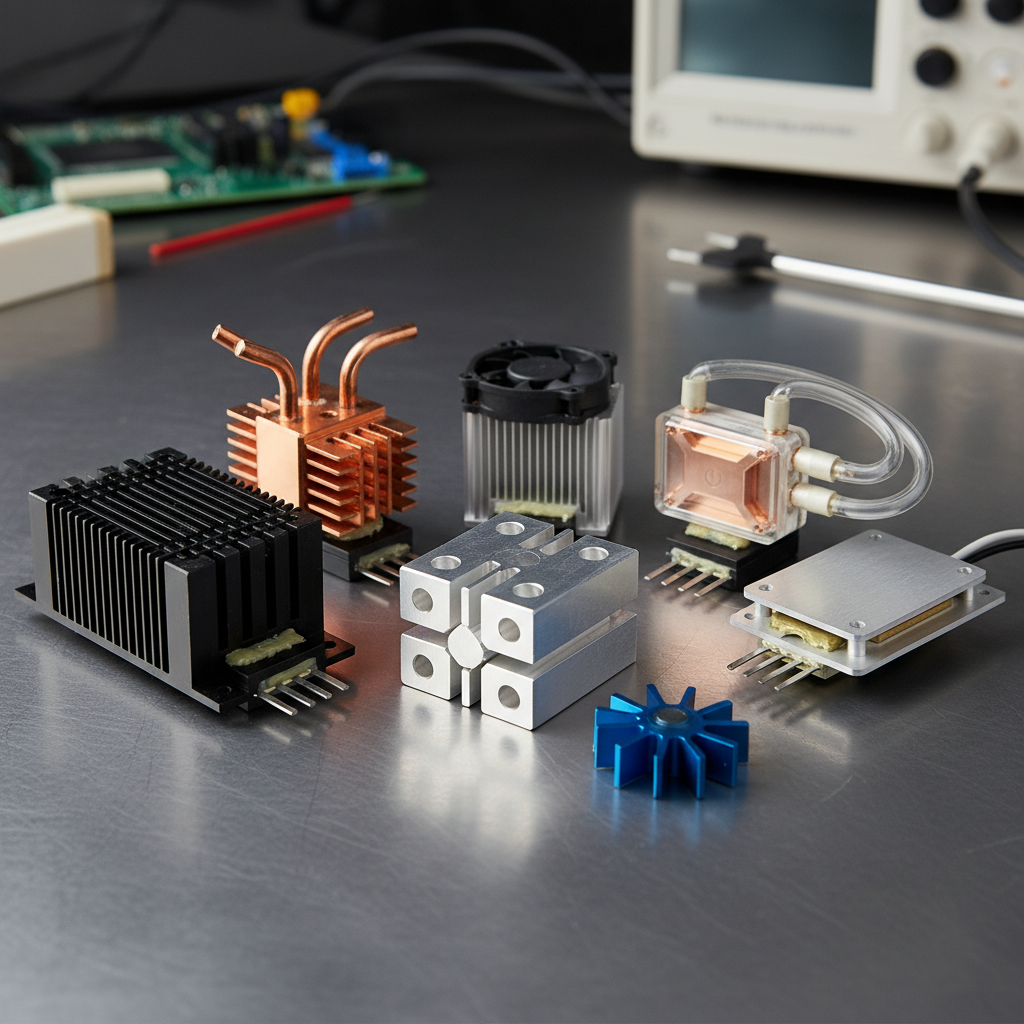

When it comes to optimizing transistor performance, selecting the right heat sink is crucial for effective cooling. There are various types of heat sinks available, each suited for specific applications. For instance, aluminum heat sinks are popular due to their excellent thermal conductivity and lightweight design, making them ideal for consumer electronics. On the other hand, copper heat sinks provide superior thermal performance and are often used in high-power applications, such as in computer processors.

Another option is the use of active heat sinks, which incorporate fans or liquid cooling systems to enhance airflow and heat dissipation. These are particularly effective in environments where passive cooling is insufficient. Additionally, heat sink designs vary from extruded to folded and fitted types, allowing for versatility in installation based on space and cooling requirements.

**Tips:** When selecting a heat sink, consider the thermal resistance needed for your specific application. Ensure to match the heat sink material with the operating environment to prevent corrosion. Also, think about the installation space; a larger heat sink may provide better cooling but requires ample room for effective air circulation.

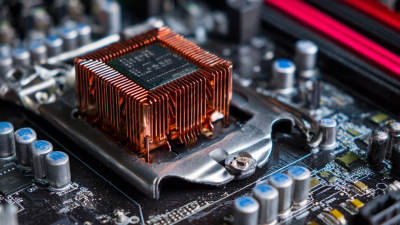

When selecting the right heat sink material for optimal transistor performance, several critical factors must be considered, including thermal conductivity, weight, and cost. Materials like aluminum and copper are commonly used due to their excellent heat dissipation properties.

According to industry reports, copper has a thermal conductivity of approximately 400 W/m·K, while aluminum offers around 205 W/m·K. This significant difference means that while copper may provide superior cooling efficiency, it is also heavier and more expensive, which might not be suitable for all applications, especially where weight constraints are paramount.

Moreover, the environmental conditions and operating temperatures should also guide the material selection process. For example, high-performance applications, such as laser operations, can produce substantial heat as only a fraction of the input power converts to light energy. Implementing effective thermal management strategies, including the right choice of heat sink material, can enhance the longevity and reliability of the system. Recent studies indicate that a well-designed heat sink can reduce thermal resistance by up to 40%, ultimately leading to improved device performance and reduced risk of failure in demanding conditions.

When it comes to achieving maximum thermal efficiency in electronic devices, understanding how to properly mount a heat sink is crucial. The first step in the mounting process is ensuring a clean interface between the heat sink and the transistor. Any residue or particles can create thermal resistance, reducing the overall cooling performance. Therefore, using isopropyl alcohol to clean both surfaces before application ensures optimal contact.

Next, consider the application of thermal paste or pads. These materials fill microscopic gaps between the surfaces, enhancing thermal conductivity. It’s essential to apply just the right amount—too little may not provide adequate coverage, while too much could lead to spillage and potential short-circuiting. Once everything is prepared, carefully position the heat sink and secure it with the appropriate mounting hardware. This stability not only ensures good thermal transfer but also extends the lifespan of both the transistor and the heat sink, contributing to better performance and reliability in high-stress environments.

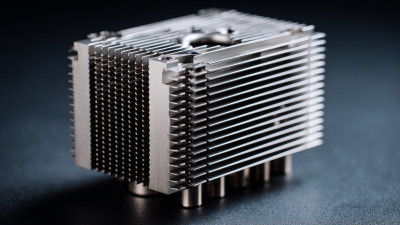

In the quest for optimal performance and longevity in electronic devices, effective heat management for transistors is crucial. Innovative passive cooling techniques have emerged as essential methods to enhance thermal performance without the need for power-consuming active systems. According to a report by Electronics Cooling, passive heat sinks can reduce temperatures by up to 30%, thereby prolonging the lifespan of components and improving overall efficiency.

One effective approach is the use of advanced materials such as copper and aluminum, which exhibit superior thermal conductivity. Additionally, incorporating finned designs can significantly increase the surface area for heat dissipation, a vital feature noted in the industry-standard Thermal Management Best Practices report. Implementing thermal interface materials (TIMs) can enhance the heat transfer between transistors and heat sinks, further optimizing cooling efficiency.

**Tip:** Ensure that your heat sink is adequately sized for the transistor to maintain optimal thermal performance. Overheating can lead to reduced efficacy and device failure. Regular maintenance checks are also advisable to prevent dust accumulation, which can hinder airflow and heat dissipation. Emphasizing these passive cooling techniques not only aids in maintaining system stability but is also aligned with the industry's push towards energy-efficient designs.

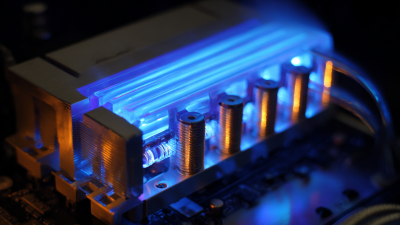

When it comes to achieving optimal performance in transistor applications, active cooling solutions play a crucial role. Fans are one of the most common methods for cooling high-performance hardware. They work by creating airflow over heated components, effectively dissipating heat and preventing thermal buildup. For those looking for an affordable and easy-to-install option, high-velocity fans can significantly enhance cooling efficiency without taking up much space.

For more demanding applications, liquid cooling systems offer superior thermal management compared to traditional fans. These systems circulate a coolant through tubes that absorb heat from the components, directing it away from critical areas. Liquid cooling not only efficiently regulates temperatures but also allows for quieter operation, which can benefit builds where noise reduction is a priority.

**Tips:** When selecting fans, prioritize models with adjustable speeds for better control over cooling performance. Additionally, ensure that your liquid cooling solution is compatible with the entire system, as improper fittings might lead to leaks or inefficiencies. Regular maintenance, including cleaning dust from fans and cooling systems, can also prolong the lifespan and efficiency of your cooling solutions.

| Solution Type | Cooling Method | Ideal Usage | Pros | Cons |

|---|---|---|---|---|

| Active Heat Sink | Fan Cooling | General Electronics | Cost-effective, easy to install | Noisy, can accumulate dust |

| Liquid Cooling System | Liquid Circulation | High-Performance Systems | Highly efficient, excellent cooling | Complex installation, potential leaks |

| Heat Pipe | Passive Cooling | Compact Devices | No moving parts, reliable | Limited cooling capacity |

| Thermal Pad | Conductive Interface | Regular Components | Easy to apply, low-cost | Less effective than other methods |

| Peltier Cooler | Thermoelectric Cooling | Custom High-End Applications | Can achieve low temperatures | Power consumption, requires heat dissipation |

| Dissipative Heat Sink | Passive Radiative Cooling | Standard Applications | Simple design, stable performance | Dependent on ambient temperature |

| Immersion Cooling | Liquid Bath | Data Centers | Highly efficient, lowers overall heat | Expensive setup, requires maintenance |